What Is Inventory Shrinkage and How Do You Stop It?

Ever had that sinking feeling when you know you bought a specific part, but when your tech goes to grab it, it’s just… gone? That’s inventory shrinkage in a nutshell.

It’s the gap between the inventory your records say you have and what’s actually sitting on your warehouse shelves or in your work vans. For a contractor, it’s like a slow, silent leak in a pipe—a constant drip that quietly drains your profits, one missing part at a time.

Understanding the Silent Profit Killer

Let’s say you stock up on 100 copper fittings for a run of plumbing jobs. Your inventory system shows all 100 are ready to go. But when your plumber counts them out for the day, there are only 95. Those five missing fittings? That's shrinkage.

While you hear about it most in retail, shrinkage hits the trades hard. The global retail industry is looking at a staggering $132 billion in projected losses for 2024 from this very problem, and that number keeps climbing. You can dig into some fascinating insights on the escalating costs of retail shrinkage to see just how big the issue has become.

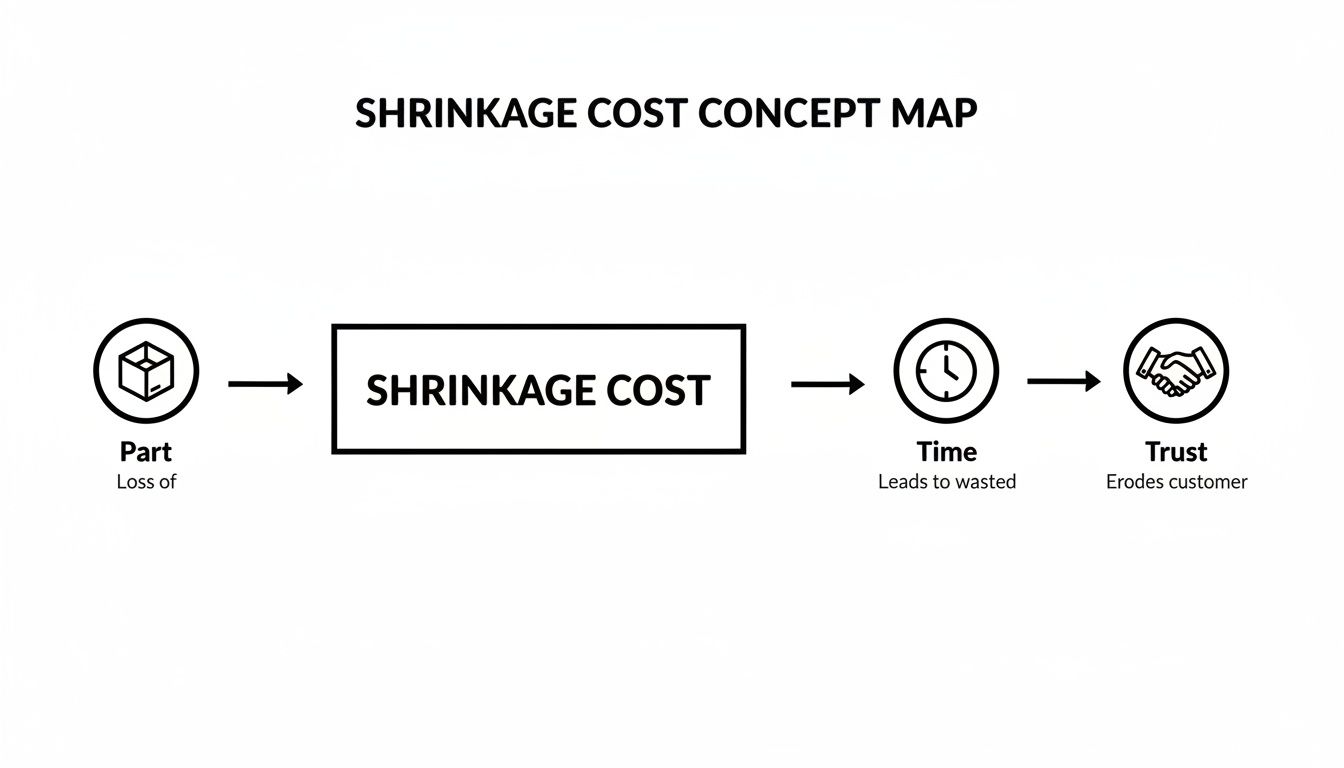

To quickly grasp the core of this issue, here’s a simple breakdown of what inventory shrinkage really means for your business.

Quick Guide to Understanding Inventory Shrinkage

| Concept | What It Means for a Contractor |

|---|---|

| The Definition | The value of parts, tools, and materials that have disappeared for reasons other than a completed, billed job. |

| The "Silent" Cost | It's not just the cost of the part; it's the wasted labor, fuel, and time spent trying to find or replace it. |

| The Ripple Effect | A missing part can delay a job, force a return trip, and damage your reputation with a frustrated customer. |

| The Bottom Line | Shrinkage directly eats into your profit margins, turning what should have been a profitable job into a loss. |

As you can see, this isn't a minor bookkeeping hiccup—it's a direct threat to your profitability.

Why Shrinkage Is More Than Just a Retail Problem

For an HVAC, plumbing, or electrical contractor, a missing part creates a painful domino effect that can throw your whole day off track. A misplaced capacitor or a lost valve isn't just a few bucks down the drain. It means:

- Wasted Trips: Your tech shows up to a customer’s house, opens the van, and realizes the one part they need isn’t there. Now they have to burn time and fuel driving back to the shop or a supply house.

- Delayed Jobs: That quick, one-hour repair just turned into a multi-day headache. The customer is annoyed, your schedule is a mess, and your reputation for being fast and reliable takes a hit.

- Eroded Profit Margins: Every single part that vanishes without being billed for directly cuts into the profitability of a job. Suddenly, that money-maker of a project is barely breaking even.

Ultimately, inventory shrinkage isn't just about lost parts. It's about lost time, lost labor, and lost customer trust—all of which are far more expensive than the missing inventory itself.

Getting a handle on shrinkage is fundamental to running an efficient operation. The first step is truly understanding its impact, and the next is putting a system in place—like a good field service management software—to track every single part from the warehouse to the final invoice.

The Five Root Causes of Shrinkage in the Trades

Knowing what inventory shrinkage is is the first step. But figuring out where it’s coming from? That’s how you actually start to fight back. Shrinkage isn't just one big event; it's the result of several different problems that can pop up in any trade business. It helps to think of it less like parts mysteriously vanishing and more like a series of small, preventable leaks in your operational plumbing.

Each one of these causes adds up to a much bigger problem. And while we often hear about shrinkage in retail, the trades deal with the exact same headaches. In fact, the losses are getting worse, fast. U.S. retail shrinkage has more than doubled in the last five years, soaring past $100 billion by 2022. With rates hitting 1.6% of sales in 2023, this isn't an issue that's going away on its own. You can discover more key trends and statistics for 2025 that show how these losses are projected to keep climbing.

If you want to protect your bottom line, you have to get specific about where your business is vulnerable. Let's dig into the five most common culprits.

1. Employee Theft

It’s an uncomfortable topic, but we have to talk about it: employee theft is a major driver of shrinkage. This isn't always some grand, malicious scheme. It's often more subtle—a tech grabbing a few extra fittings for a side job or "borrowing" a specialty tool and conveniently forgetting to bring it back.

Without a solid system that links every single part to a specific work order, these tiny losses add up fast. Spread across an entire team over a year, they become a massive drain on your profits.

2. Administrative and Clerical Errors

Good old-fashioned human error is one of the most common—and most underestimated—causes of inventory shrinkage. We’re talking about the simple slip-ups that throw your counts completely out of whack and create "phantom inventory."

- Receiving Errors: Your warehouse manager is in a rush and miscounts a shipment of thermostats, signing off for 50 when only 48 were actually delivered.

- Data Entry Mistakes: An office admin accidentally types "10" instead of "1" when logging a box of circuit breakers. Now your system is off, and you might not find out for months.

- Pricing Errors: An item is priced incorrectly in the system, leading to under-billing. It's a financial loss that feels just like a physical part walking out the door.

These little mistakes seem minor, but they create chaos in your inventory records, making it impossible to trust the numbers you see on the screen.

3. Job Site and Transit Damage

The trades are tough on materials. Parts get damaged long before they ever have a chance to be installed. A box of delicate HVAC sensors gets crushed under heavier gear in a packed van, or a technician fumbles and drops an expensive control board from the top of a ladder.

When a part is damaged and tossed aside without being properly logged, it instantly becomes shrinkage. Your inventory system still thinks that part is ready to go, which leads to major scheduling headaches and a frantic search when another tech needs it for their next job.

4. Supplier and Vendor Issues

Sometimes, your inventory count is wrong before the parts even hit your shelves. Supplier fraud and simple vendor errors are a surprisingly common source of shrinkage that starts the moment a delivery arrives. This can look like:

- Short Shipments: Your supplier bills you for 100 feet of copper pipe but only sends 90 feet.

- Incorrect Parts: You get a cheaper, lower-quality version of a component but are invoiced for the premium model you actually ordered.

If you don't have a rock-solid receiving process where every delivery is meticulously checked against the purchase order, these discrepancies slide by unnoticed and get absorbed as a loss.

5. Operational and Process Gaps

Finally, a huge amount of inventory loss comes from nothing more than disorganized internal processes. This is the catch-all for untracked part usage, sloppy van restocking workflows, and a general lack of accountability. When a tech uses a part but forgets to log it, that item effectively disappears from your records. It just became another casualty of inventory shrinkage.

How to Calculate Your Inventory Shrinkage Rate

You can’t fix a problem you can’t measure. Calculating your inventory shrinkage rate is the first step toward plugging those profit leaks. It takes that vague, nagging feeling that you're losing parts and turns it into a hard number you can actually do something about. Think of it as the diagnostic tool for the health of your inventory.

The good news? You don't need a degree in accounting to figure this out. The math is simple, but it does demand a commitment to getting a true and accurate count.

The Shrinkage Rate Formula

At its core, the formula just compares what your books say you have versus what's actually sitting on the shelves.

Shrinkage Rate = (Recorded Inventory Value – Actual Physical Value) / Recorded Inventory Value

To turn this into a percentage, just multiply the final number by 100. This percentage tells you exactly how much of your inventory's value has disappeared from theft, damage, or simple mistakes.

A Step-by-Step Calculation Guide

Let's walk through a real-world example for a plumbing contractor to see how it works.

-

Find Your Recorded Inventory Value: First, you need the official value of the inventory on your books. This number should be in your inventory management system or accounting software. It’s the total dollar value of everything you've purchased and haven't sold yet. For our example, let's say your records show $250,000 worth of parts.

-

Conduct a Physical Inventory Count: This is the most important—and often most tedious—part. You have to physically count every single fitting, valve, and pipe in your warehouse and on every truck. No shortcuts. Once you have the quantities, multiply each item by its cost to find your Actual Physical Value. Our plumber does a full count and discovers they only have $244,000 worth of parts.

-

Calculate the Difference: Now, subtract the actual value from what your records claimed.

- $250,000 (Recorded) – $244,000 (Actual) = $6,000 in lost inventory value.

-

Determine the Shrinkage Rate: Finally, plug those numbers into the formula we talked about.

- ($6,000 / $250,000) * 100 = 2.4% Shrinkage Rate

That 2.4% is a direct hit to the company’s bottom line. While every business expects some shrinkage, anything over 1% is a massive red flag that your processes are broken and actively costing you money.

Knowing this number is also vital when you simplify estimates, quotes, and invoicing, because it ensures your job costs are based on reality—not just what the spreadsheet says you should have.

The True Cost of Shrinkage on Your Bottom Line

That one missing $50 part? It's never just a $50 loss. The real damage from inventory shrinkage comes from the hidden costs that ripple through your entire operation, quietly eating away at your profits. It’s a domino effect, turning a simple missing component into a cascade of financial and operational headaches.

This goes way beyond the sticker price of the item. Every time a part vanishes, it chips away at the profit margin on that specific job and inflates your overall operating costs. Suddenly, you're shelling out for rush orders to replace the missing piece and eating the cost of a technician's wasted time.

Unpacking the Ripple Effect

Let’s get practical. Imagine an HVAC tech arrives at a home for a furnace installation. The job is scheduled, the customer is waiting, but a critical capacitor is missing from the van—even though the system said it was there.

The financial damage starts ticking up immediately:

- Lost Labor Costs: Your technician's paid time is now spent frantically searching the van, calling the office, or driving to a supply house instead of completing the billable work.

- Return Trip Expenses: A second trip is now on the books, doubling the fuel costs and vehicle wear-and-tear for that one job.

- Delayed Cash Flow: The job can't be finished and invoiced, pushing back payment and throwing a wrench in your expected revenue stream.

This isn't just an inconvenience; it’s a direct hit to your bottom line. Each of these consequences stacks up, turning what should have been a profitable project into a break-even task or, worse, a loss.

To truly grasp the impact, let's break down the hidden costs tied to that single missing $50 part.

Hidden Costs of a Single Missing Part

| Cost Category | Estimated Financial Impact |

|---|---|

| Cost of Missing Part | $50.00 |

| Wasted Technician Labor (1 hr @ $75/hr) | $75.00 |

| Fuel & Vehicle Costs for Supply Run | $25.00 |

| Administrative Time (Ordering, Rescheduling) | $30.00 |

| Delayed Invoicing (Impact on Cash Flow) | Varies |

| Rush Order/Overnight Shipping Fees | $40.00 |

| Total Tangible Cost | $220.00+ |

| Intangible Costs | Reputational Damage, Lost Future Business |

As you can see, the problem is nearly 5x worse than it first appeared, and that’s before accounting for the damage to your customer relationships.

The Broader Business Impact

The problem gets even bigger when you look beyond a single bad job. As parts go missing, you're also fighting against external forces you can't control. Recent supply chain disruptions have become a massive headache, with out-of-stocks alone costing businesses nearly $1 trillion globally. You can see the full picture in this in-depth analysis of shrinkage in retail stores.

When you mix these outside pressures with internal disorganization, the damage multiplies. The true cost of what is inventory shrinkage bleeds well beyond your financial statements.

The most significant, long-term damage is often to your reputation. A customer who has to reschedule because you were missing a part remembers the inconvenience and frustration. That single negative experience can erode the trust you worked so hard to build, leading to bad reviews and lost future business.

Ultimately, sloppy inventory control doesn't just create accounting headaches. It directly hammers your cash flow, strains customer relationships, and puts a hard ceiling on how much your company can grow. Recognizing these hidden costs is the first step to understanding why proactive inventory management isn’t a "nice-to-have"—it's a necessity for survival.

Proven Strategies to Control Inventory and Stop Profit Leaks

Knowing what causes inventory shrinkage is one thing, but actually stopping it is another. The real challenge is moving from just understanding the problem to implementing a clear, actionable game plan to plug those profit leaks for good. This isn't about one magic fix; it's about a two-pronged attack: actively finding the discrepancies you already have and proactively stopping future losses before they happen.

The key is to shift from putting out fires to building a fireproof system. This means leaving behind manual, error-prone spreadsheets and embracing a more systematic, technology-driven approach that builds accountability into your daily operations. For a deeper dive, this guide on how to reduce shrinkage offers some great additional insights.

This isn't just about losing a part. A missing component creates a domino effect—wasting a technician's time, delaying a job, and ultimately damaging the customer trust you've worked so hard to build.

The ripple effects of a single lost part often cost far more than the part itself.

Implement Rigorous Detection and Auditing

Let’s be honest: you can't manage what you don’t measure. Regular, disciplined inventory audits are non-negotiable if you want to catch shrinkage early. Instead of dreading a massive year-end count, smart contractors break the process down into manageable chunks.

- Cycle Counts: Don't try to count your entire warehouse at once. Split your inventory into smaller, logical groups—like all thermostats one week, all copper fittings the next. This turns auditing into a consistent, low-stress habit instead of a once-a-year nightmare.

- Spot Audits for Service Vans: Think of your work vans as mini-warehouses on wheels, because that's where most shrinkage happens. Run random, unannounced spot checks on one or two vans each month. Compare the physical parts on board with what your system says should be there. This simple act creates a powerful culture of accountability.

These audits give you the hard data you need to see exactly where the leaks are—whether it's a specific type of part, a particular van, or a broken process that needs fixing.

Adopt Modern Prevention Tools

Detection helps you find yesterday's problems, but prevention is what stops tomorrow's. This is where modern field service management software becomes your best defense against inventory shrinkage. Tools like TackonFSM are built from the ground up to automate controls and close the very gaps where parts tend to vanish.

By embedding inventory tracking directly into your daily job workflows, you transform accountability from a manual chore into an automatic, seamless process. The system does the heavy lifting, ensuring no part leaves a van without being accounted for.

Here’s how a purpose-built platform shuts down the root causes of shrinkage:

-

Real-Time Van-Level Tracking: Stop guessing what each tech has in their truck. TackonFSM provides a live, accurate view of every single part on every van. This immediately cuts down on over-ordering, stops techs from hoarding parts "just in case," and makes sure they show up to the job with what they need the first time. It's a core feature of any field service scheduling software that saves time.

-

Linking Parts to Jobs: This is the ultimate accountability check. With TackonFSM, a part can’t be marked as "used" unless it's digitally assigned to a specific work order. This simple workflow makes undocumented part usage a thing of the past and gives you a crystal-clear audit trail for every job.

-

One-Touch Billing and Invoicing: Once a part is linked to a job, it flows straight onto the estimate and final invoice. This clean, digital handoff eliminates manual entry errors and guarantees every single fitting, wire, and valve used is billed to the customer. Your profit margins are protected automatically.

By automating these crucial control points, you can finally turn inventory management from a constant headache into a real competitive advantage.

Frequently Asked Questions About Inventory Shrinkage

Even after you get the basics down, tackling inventory shrinkage in the real world can bring up some tricky questions. When contractors start digging into their own processes, they often run into the same practical hurdles. Let's break down some of the most common questions we hear from owners in the HVAC, plumbing, and electrical trades.

What Is a Good Inventory Shrinkage Rate?

In the wider retail world, you’ll often hear an average shrinkage rate of around 1.6%. But for trade businesses handling expensive parts like compressors, circuit breakers, and water heaters, that number should be much, much lower.

A well-oiled operation using modern inventory software should be aiming for a shrinkage rate below 1%. If you're hovering between 1-2%, it’s not a disaster, but it’s a clear sign that you have profit leaks that need plugging. Anything over 2% is a serious red flag—it means systemic issues are quietly draining thousands of dollars from your business every year.

How Often Should I Do a Full Inventory Count?

Let's be honest: a full physical inventory count is a beast of a task. Counting every single part in the warehouse and on every truck is a massive, time-consuming effort. Because of that, most contractors can realistically only get this done once or twice a year.

But waiting a full year to find out you have a problem is a recipe for disaster.

The smart move is to supplement those big annual counts with regular cycle counts. This just means you're counting small, manageable sections of your inventory on a rolling basis—maybe all your capacitors one week, and all your copper fittings the next. It turns a monumental task into a simple routine and helps you catch discrepancies almost as they happen.

Can Software Eliminate All Inventory Shrinkage?

While it would be great to say yes, no system can get you to 100% elimination. A determined thief will still try to steal, and accidents can still happen. However, the right field service management platform gets you incredibly close by tackling the root causes of shrinkage: human error and messy processes.

It does this by building guardrails into your daily workflow. For instance, a part can't be marked as "used" until it's digitally assigned to a specific job, which all but stops undocumented usage in its tracks. With real-time van tracking, you always know what's on each truck, preventing overstocking and lost parts. It shifts your inventory management from a reactive headache to a proactive, automated system.

Is Inventory Software Worth It for a Small Team?

Without a doubt. In many ways, small teams feel the pain of shrinkage even more than larger companies. When you're running a lean operation, the cost of just a few missing high-value parts—like a furnace control board or a smart thermostat—can completely erase the profit from several jobs.

Putting a solid system in place while your team is small creates the right habits from the very beginning. It builds a scalable foundation, preventing the small inventory drips from turning into a flood as you grow. It's about protecting your hard-earned profit margins at every stage of your business.

Ready to stop profit leaks and get total control over your parts and materials? TackonFSM gives you real-time van tracking, job-part linking, and automated workflows to crush inventory shrinkage. See how TackonFSM can protect your bottom line today.