A Modern Electrician Pricing Guide for Maximum Profit

Pricing your electrical work can feel like you’re walking a tightrope. Price too high, and you won’t get the job. Price too low, and you might as well have stayed home. A real electrician pricing guide isn’t just a menu of services; it’s a formula that guarantees you make money on every single job. It’s about moving past a simple hourly rate to a system that actually covers what your labor costs, what it takes to keep the business running, and leaves a healthy profit.

Building a Bulletproof Pricing Foundation

Let's be blunt: setting the right price is the most critical thing you can do to stay in business. It’s what determines your cash flow, whether you can afford that new van or better tools, and what you ultimately take home. Too many electricians fall into the trap of just matching what the other guy down the street charges. That’s a race to the bottom. You have no idea what his overhead looks like or if he’s one bad job away from closing his doors for good.

A solid pricing strategy is built from your own numbers, from the inside out. Think of it like wiring a house. You wouldn't start pulling wire without a solid plan and a properly sized panel. In the same way, you can’t just throw numbers at a customer without first understanding every single cost that goes into running your business. This method takes the guesswork out of pricing and gives you the confidence that you’re charging what you’re worth.

The Three Pillars of Profitable Pricing

Every quote you build, whether it's for a quick switch replacement or a full service upgrade, needs to stand on three pillars. If you miss one, you’re either leaving money on the table or, even worse, paying to do the work.

- True Labor Costs: This is so much more than what you pay your tech per hour. You have to account for payroll taxes, workers' comp, benefits, and paid time off. Don't forget the non-billable time either—the hours spent driving to the supply house or sitting in traffic between jobs.

- Overhead Expenses: These are the silent killers of profit. It’s all the money you spend just to be able to open your doors each day: van payments, gas, insurance, software subscriptions, marketing, your phone bill, and rent.

- Profit Margin: Profit isn’t a dirty word. It’s the reward you get for taking the risk of running a business. Profit is what lets you grow the company, handle a van breaking down unexpectedly, and invest in the future.

Once you’ve accurately calculated these three pillars, you can figure out your break-even rate. This is the rock-bottom, absolute minimum you have to charge per hour just to cover your costs, without making a dime of profit.

Knowing your break-even rate is a game-changer. It sets a hard floor for your pricing. Any job you price below that number is a guaranteed loss. Anything above it is profit in your pocket.

Why "Gut Feeling" Pricing Fails

Many electricians, especially when starting out, price jobs based on a gut feeling or by multiplying their desired hourly wage by the estimated time. This is a recipe for disaster because it completely ignores the massive cost of overhead. Charging $75 an hour might sound decent, but if your actual costs for labor and overhead add up to $60 an hour, you're only pocketing $15 for all that work.

That’s not a sustainable way to run a business. You end up constantly chasing the next check just to pay this month’s bills. When a big, unexpected expense pops up—and it always does—there’s no cash reserve to handle it. The whole point of this guide is to shift your thinking from just covering the costs of a single job to making sure every hour you bill contributes to the long-term financial health of your entire business. This foundation ensures every call you run builds your bottom line and sets you up for success.

Figuring Out Your True Labor and Overhead Costs

So many electricians make the same mistake right out of the gate: they base their prices on what they pay an employee per hour. But an electrician’s real cost is so much more than their paycheck. To build a pricing model that actually makes you money and keeps the lights on, you have to calculate your fully-loaded labor cost. This number includes every single expense tied to having that person on your team.

Think of it like this: the price you pay for a gallon of gas isn't just the cost of crude oil. It also covers refining, shipping it across the country, taxes, and the gas station's own costs to operate. In the same way, your technician's hourly rate has to cover a lot more than just their wage to be accurate.

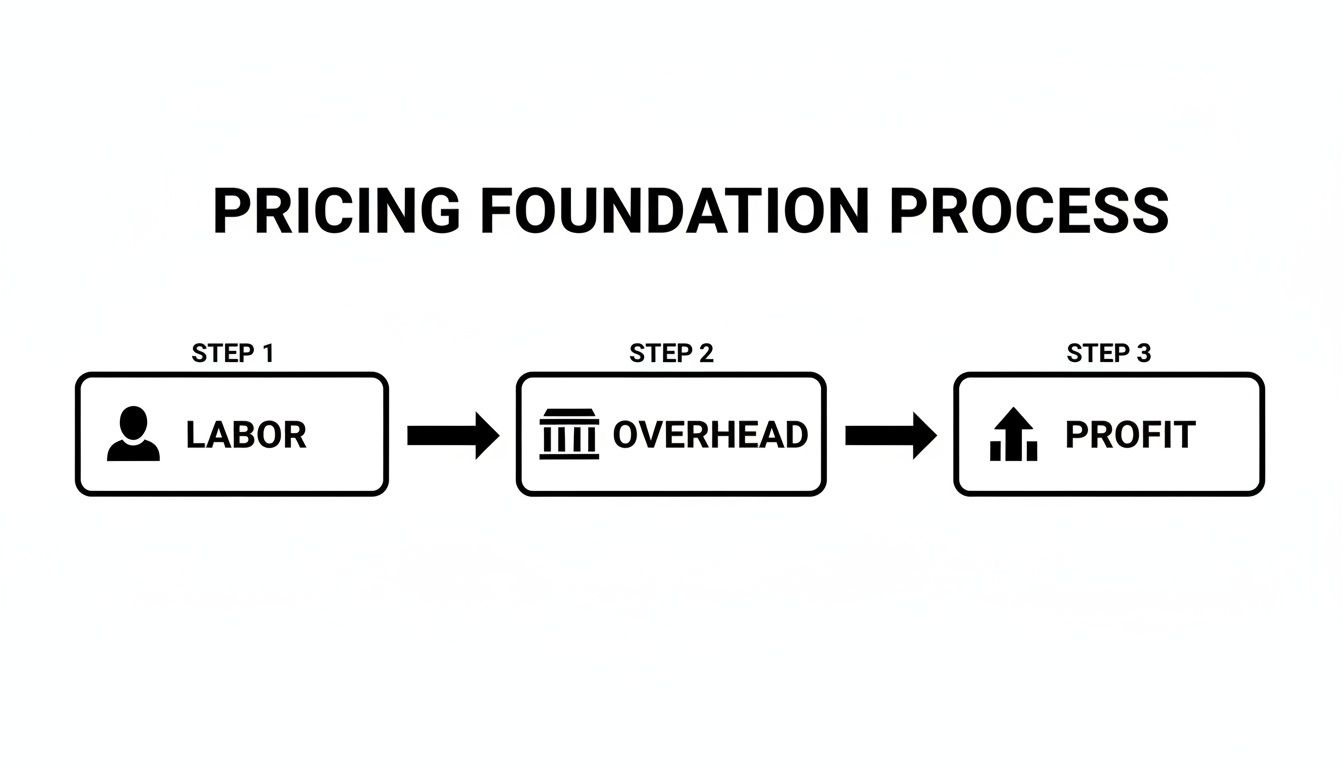

This flowchart breaks down how Labor, Overhead, and Profit build on each other to create a rock-solid pricing foundation.

When you follow this process, you make sure no cost gets missed. It guarantees every quote you send is designed to be profitable from the very start.

Unpacking Your Fully Loaded Labor Cost

Your fully loaded labor cost is what it really costs you to have a technician working for one hour. This figure includes the obvious stuff and the costs that are easy to forget but directly support your crew in the field.

To get this number, you'll start with their base hourly wage and then start piling on all the extras. These aren't optional—they are real, consistent expenses that will bleed your margins dry if you ignore them.

Here are the key things that make up your true labor cost:

- Wages and Payroll Taxes: This is the technician's hourly pay, plus your share of FICA, Medicare, and unemployment taxes.

- Insurance: Don't forget workers' compensation, your general liability policy, and any contributions you make to health insurance plans.

- Benefits: Factor in paid time off (vacation, sick days), any 401(k) or retirement contributions, and other perks you offer.

- Training and Certifications: The cost of continuing education, license renewals, and safety training all go here.

- Uniforms and Gear: Include the price of branded shirts, personal protective equipment (PPE), and other gear they need to do the job.

By adding all these direct costs together, you stop thinking about a simple wage and start using a powerful number that reflects the true expense of your team.

Nailing Down Your Overhead

Next up is overhead—the silent profit killer. Overhead covers all the indirect costs you have just to keep your business running, separate from the labor and parts for a specific job. These bills keep coming, whether your team is busy on a job site or not.

Ignoring overhead is like trying to drive your work van without ever thinking about the cost of gas, insurance, or maintenance. Sooner or later, you'll run out of fuel and be stranded on the side of the road.

Your mission here is to calculate your total annual overhead. Comb through your books and add up every single business expense that isn't a direct labor cost or a part for a job. Getting this number right is a cornerstone of any good pricing strategy.

Common overhead expenses you need to track:

- Facility Costs: Rent for your office or shop, utilities, and property taxes.

- Vehicle Expenses: Van payments or leases, fuel, insurance, registration, and all the maintenance and repairs.

- Software and Technology: Your monthly bill for field service management software, accounting tools, and your phone system.

- Administrative Salaries: Pay for your office manager, dispatcher, or anyone not directly billing hours in the field.

- Marketing and Advertising: The budget for your website, Google Ads, and any other way you get the word out.

- Professional Services: What you pay your accountant, lawyer, or other consultants.

You can see how a field service management dashboard can give you a bird's-eye view to help monitor and manage these critical business numbers.

Turning Overhead into an Hourly Rate

Okay, once you have your total annual overhead cost, the last step is to break it down and assign a piece of it to every single billable hour. This is how you make sure every job pays its fair share to keep the business running.

First, you need to calculate your total annual billable hours. This isn't just 40 hours a week times 52 weeks. You have to subtract all the non-billable time, like holidays, vacation, sick days, training, and even travel time between jobs. For most electricians, a realistic number is somewhere around 1,500-1,700 billable hours per tech, per year.

Now, just plug your numbers into this simple formula:

Total Annual Overhead / Total Annual Billable Hours = Overhead Cost Per Hour

Let's say your annual overhead is $150,000 and your team produces 3,000 total billable hours in a year. Your overhead cost is $50 per hour ($150,000 / 3,000).

This $50 must be added to your fully-loaded labor cost just to find your break-even point. This is the rate you need to charge before you've made a single penny of profit. Doing this math protects your business and ensures every quote is built on a foundation of real numbers.

Mastering Material Markups for Profitability

Once you’ve nailed down your true labor and overhead costs, the next piece of the puzzle is your materials. Let’s be honest: volatile material costs can sink a good job fast if you’re not paying attention. Just passing the cost of parts along to the customer is a huge mistake. You should be treating every single part as its own little profit center.

This means you need a smart markup strategy. A good system does more than just cover the cost of a part; it protects your margins from sudden price hikes and, just as importantly, pays you for all the hidden work that goes into getting that part to the job site. Think about the time spent sourcing materials, driving to the supply house, managing what’s in the van, and dealing with returns. That’s all billable time, and your markup is how you capture it.

This isn’t just good advice; it’s essential for survival right now. We've all felt the sting of rising prices. The overall electrical price index has jumped 4.6% in just the last year. Some items are even worse—circuit breakers are up 8.7%, power wire and cable shot up 8.2%, and generators have seen a 7.2% increase. If your pricing doesn't keep up, that's pure profit evaporating from every job.

Choosing Your Markup Model

Not all parts are the same, so why would you use the same markup for everything? A flat percentage across the board is better than nothing, but a tiered approach is where the real money is made. The goal is to maximize your profit on the small, everyday items while staying competitive on the big-ticket stuff.

One of the best ways to do this is with a tiered pricing matrix. It’s pretty simple: you apply a higher markup to less expensive parts and a lower one to more expensive components. This way, you’re properly compensated for stocking and handling all those small parts without scaring a customer off a big job that needs a new service panel. When figuring out your markups, don't forget to account for the current solar inverter prices and costs, as they can be a major part of many modern projects.

Think of it like a sliding scale. You might put a 100% markup on a $5 outlet but only a 20% markup on a $1,500 generator. This balanced approach keeps your overall job margin healthy without making a customer feel like they’re being gouged on the expensive equipment.

Building a Centralized Parts Pricebook

Consistency is the name of the game. If one tech charges one price for a breaker and another tech charges something different, you’re going to have confused customers and unpredictable profits. The solution is a centralized parts pricebook.

This becomes your single source of truth for every part you use—what it costs you and what you sell it for. Using a digital pricebook, especially one built into your field service management (FSM) software, makes sure every estimate is built from the same profitable numbers.

Here’s why a digital pricebook is a must-have tool for any serious electrical business:

- Enforces Consistency: Everyone on your team is singing from the same hymn sheet. No more random pricing.

- Protects Margins: Your markups are baked right in, making it almost impossible to undercharge by mistake.

- Improves Speed: Techs can find parts and build an accurate quote in minutes, right on the spot, without having to call the office.

- Adapts to Change: When the cost of copper skyrockets overnight, you can update your pricing across the entire system instantly.

By setting a clear markup strategy and locking it in with a centralized pricebook, you stop treating materials like a liability and start turning them into a reliable profit generator. It’s how you get paid for your expertise in sourcing and managing materials, and it adds directly to your bottom line on every single job.

Structuring Your Electrical Service Menu

Once you've nailed down your true costs for labor, overhead, and parts, you have all the essential ingredients for a profitable business. The next step is to put them together into a clear, customer-friendly service menu. A well-organized menu takes the guesswork out of pricing, builds trust with clients, and makes sure every job you do is set up for success.

Think of it like a restaurant menu. You don't just see a single price for "food." Instead, you have different prices for appetizers, main courses, and desserts, each one reflecting the unique ingredients and work that goes into it. Electrical services are no different—a quick diagnostic visit is a totally different beast than a full-day panel upgrade.

The whole point is to build a system that’s easy for your team to use and simple for customers to understand. When pricing is transparent, it cuts down on sticker shock and helps people see the value you're providing. Suddenly, your pricing isn't just a number; it's a competitive advantage.

Pricing for Different Service Call Types

Let's face it, not all electrical work fits neatly into a one-size-fits-all box. Your pricing needs to be flexible enough to cover everything from a five-minute fix to a multi-day project. The real trick is matching the right pricing model to the nature of the work.

Across the US, you'll see hourly rates for electricians generally falling between $50 and $130. Most companies also have a minimum service call charge of $100 to $200 just to roll a truck. Of course, experience matters. Apprentices might bill out at $40-$60 per hour, while journeymen command $60-$90. A master electrician handling complex jobs can easily be in the $90-$120 range.

Let's break down the most common ways to structure your pricing:

- Diagnostic & Service Calls (Trip Charge + Hourly): When you're heading out to troubleshoot an unknown problem, a minimum trip or dispatch fee is non-negotiable. This fee covers the hard costs of getting a trained tech and a stocked van to the customer’s door. After an initial period, say the first 30 or 60 minutes, the clock starts, and you bill at your standard hourly rate.

- Standard Projects (Hourly Rate): For jobs where the scope is a bit of a moving target—like fishing wires through old lath and plaster walls or handling small remodeling tasks—an hourly rate is often the fairest way to go for both you and the client.

- Common Installations (Flat-Rate Pricing): This is where the money is. For predictable, repeatable jobs like installing a ceiling fan, adding a new outlet, or putting in an EV charger, flat-rate pricing is king. You already know what parts you'll need and roughly how long it will take. This gives the customer a solid, upfront price and takes away their anxiety about a job dragging on.

Sample Electrician Service Pricing Tiers

To give you a clearer picture, here’s a look at how these pricing models can be applied to common electrical services, factoring in different experience levels.

| Service Type | Experience Level | Typical Hourly Rate | Example Flat-Rate Price |

|---|---|---|---|

| Diagnostic Service Call | Journeyman | $75 – $95 | $175 (includes first 60 mins) |

| Standard Outlet Install | Journeyman | $60 – $90 | $225 – $350 |

| GFCI Outlet Install | Journeyman | $60 – $90 | $275 – $400 |

| Ceiling Fan Installation | Apprentice/Journeyman | $50 – $85 | $300 – $550 |

| EV Charger (Level 2) | Master Electrician | $90 – $120 | $800 – $1,500 |

| Panel Upgrade | Master Electrician | $100 – $130 | $2,500 – $4,500 |

This table illustrates how you can build a versatile pricing structure. For routine tasks, a flat rate provides clarity, while hourly rates offer the flexibility needed for custom or unpredictable work.

Establishing Your Flat-Rate Pricebook

Flat-rate pricing is an incredibly powerful tool for winning more jobs and protecting your profit margins. It shifts the conversation from "How much do you charge per hour?" to "What's the total investment to get this done right?" It takes a little homework to set up a pricebook, but the payoff is huge.

Building a flat-rate price is actually pretty straightforward. You just combine your known costs for a specific task.

Flat-Rate Formula: (Estimated Labor Hours x Your Fully-Loaded Hourly Rate) + Total Material Cost (with Markup) = Your Flat-Rate Price

For example, let’s say you’re pricing out a NEMA 14-30 outlet install for an EV charger. You’d calculate the cost of the outlet, wire, and breaker (with your markup applied), then add the cost of your electrician's time to get the job done. Simple as that.

Setting Premium Rates for Urgent Calls

Finally, your service menu isn't complete without a plan for calls that come in after 5 PM or on a Sunday morning. Emergency and after-hours work demands a premium rate. Why? Because it disrupts schedules, pulls technicians away from their families, and requires an immediate, on-call response.

It's standard practice in the industry to charge 1.5x to 2x your normal rate for these calls. This isn’t about taking advantage of a bad situation; it's fair compensation for the urgency and availability your team provides. Just make sure this premium is clearly communicated to the customer when they call, so there are no ugly surprises on the final bill. When you learn how to simplify estimates, quotes, and invoicing, you can make these conversations smooth and professional every time.

Using Technology to Enforce Profitable Pricing

A rock-solid pricing strategy is a fantastic start, but it's only as good as its execution in the field. All the careful math you do in the office—calculating labor, overhead, and material costs—means nothing if those numbers aren't used consistently on every single job. This is where modern field service management (FSM) software becomes your secret weapon, turning your pricing playbook from a document on a shelf into a daily reality.

Think of FSM software as the central nervous system for your entire operation. It connects the pricing rules you set in the office directly to your technicians' tablets, getting rid of the guesswork, scribbled notes, and back-of-the-napkin math that kill your profit margins. It's the tool that makes sure every estimate you send actually protects your bottom line.

This digital estimate, built right on-site, shows just how professional and consistent your pricing can look with the right software.

When you give your techs the ability to build quotes from pre-loaded parts and labor rates, you eliminate those wild price variations and present a polished, trustworthy estimate to every customer.

From Pricebook to Profitability

The heart of this entire system is a digital pricebook. Forget about techs trying to remember prices or flipping through outdated paper catalogs. Your entire inventory of parts and services lives in one central place, with your calculated cost, markup, and final price already baked into every single item.

This completely changes how your team builds quotes.

When a technician is standing in a customer's home, they can pull together a detailed, accurate estimate in just a few minutes. They simply tap to select the parts and labor needed, and the software handles the rest, automatically applying the correct pricing. For complex bids, specialized tools like Exayard electrical estimating software can provide an even greater level of detail and accuracy.

This approach gives you a few major advantages:

- Margin Enforcement: You can set minimum profit margins right in the system. If a quote dips below your target, it gets flagged, preventing accidental underbidding before it ever reaches the customer.

- Standardized Labor Rates: Your fully-loaded labor cost is applied the same way every time. No more guessing—just consistently profitable billing for every hour worked.

- Up-to-Date Material Costs: When your supplier raises the price on copper wire, you update it once in your FSM. That new price is immediately reflected in every new estimate your team creates.

Streamlining the Entire Workflow

Good technology does more than just build a quote; it smooths out the entire process from estimate to payment. This saves a ton of administrative headaches and, most importantly, gets you paid faster.

An accurate quote that sits unapproved for a week is just lost revenue. Technology closes the gap between quoting and getting the work started, improving cash flow and customer satisfaction.

Modern FSM platforms digitize the whole workflow. Your tech can present the estimate on a tablet and get a digital signature for approval right then and there. The moment it's signed, that estimate instantly becomes a work order, with all the necessary parts and job details ready to go.

Getting Paid Faster with Integrated Payments

The final piece of the puzzle is collecting the money. Once the job is done, that work order converts into an invoice with a single click. No more technicians bringing paperwork back to the office for someone to manually type up and mail out.

With integrated payment processing, you can get paid on the spot.

- In-Field Payments: Techs can securely swipe a credit card using a mobile reader.

- Payment Links: You can text or email a secure link, and the customer can pay online from their phone or computer.

This simple change can dramatically shorten your payment cycle. Instead of waiting weeks for a check to show up, you can have funds in your account within a couple of days. If you want to learn more, you can see how field service management software matters for both efficiency and your bottom line. By putting technology to work, you truly put your pricing strategy into action, cutting down on errors and ensuring every job is a profitable one.

Common Questions (and Smart Answers) About Electrician Pricing

Even the most buttoned-up pricing strategy will face real-world curveballs. This is where the rubber meets the road—handling the tricky situations and questions that inevitably pop up. Think of this as your playbook for navigating those tough conversations about money.

From justifying your rates to managing client expectations, how you handle these moments is just as important as the quality of your wiring. Getting this right builds trust, solidifies your reputation, and protects your bottom line for the long haul.

When Should I Use Flat-Rate vs. Hourly Billing?

This is the big one, and the truth is, you need both in your toolkit. The real skill is knowing which pricing model to pull out for which job.

Use flat-rate pricing for the jobs you’ve done a hundred times. These are the predictable, repeatable tasks where you can confidently estimate the time and materials needed.

- Good for: Installing a ceiling fan, swapping a standard outlet for a GFCI, or setting up a pre-wired EV charger.

- Why it works: The customer gets a solid, upfront price, which eliminates their anxiety about a running clock. It also rewards your team's efficiency—if you get the job done faster than planned, your profit margin gets a nice boost.

Use hourly billing (always with a minimum trip charge) for diagnostic work, troubleshooting, and any project full of unknowns.

- Good for: Chasing down a mysterious short circuit, fishing wires through old plaster and lath walls, or tackling a complex custom lighting project.

- Why it works: This is your safety net. It protects you from losing money on a job that turns out to be ten times more complicated than it first appeared. You get paid fairly for every minute of your expertise.

How Do I Handle Price Objections from Customers?

Nobody likes hearing their price is "too high," but it’s going to happen. The trick is to not get defensive. Instead, see it as an invitation to explain the value you bring to the table. A price objection isn't always a hard "no"—it's often just a request for more information and a bit of reassurance.

When a customer pushes back on your quote, try this approach:

- Don't Jump to a Discount: Slashing your price right away signals that it was inflated to begin with. First, ask some questions to figure out what’s really behind their hesitation. Is it a genuine budget issue, or do they just not see the value yet?

- Reiterate What They're Paying For: Gently walk them through what your price covers. "I understand it's a significant investment. Our price includes a fully licensed and insured master electrician, high-quality materials that won't fail in a few years, a two-year warranty on our workmanship, and us handling all the necessary permits and inspections."

- Offer Options, Not Discounts: If budget is the real roadblock, see if you can offer different solutions. "We could look at a different brand of fixtures to bring the cost down, or we could tackle this as a two-phase project to help spread out the investment."

A confident explanation is your best tool. When you can clearly articulate why your services cost what they do—covering insurance, quality parts, and expert labor—you shift the conversation from price to value.

How Should I Communicate a Price Increase to Long-Term Clients?

Raising your rates is a non-negotiable part of running a healthy business, but it can feel incredibly awkward with loyal customers. The key is to be transparent, proactive, and appreciative. Whatever you do, don't let them find out on their next invoice.

Give them a heads-up—at least 30 to 60 days in advance. Frame the change positively by explaining why it's happening. You’re not just raising prices; you’re making adjustments so you can keep delivering the top-tier service they’ve come to expect.

For example, you could say:

"To keep investing in the best tools, ongoing training for our team, and the high-quality materials you deserve, we're adjusting our service rates starting [Date]. This change ensures we can continue to provide the reliable, safe, and professional service you've always counted on from us."

This approach respects the relationship and frames the increase as a benefit to them, not just your wallet. Everyone understands that costs go up. In fact, the average residential electricity bill in the US is projected to climb over 30% between 2021 and 2025 alone. You can discover more about how electricity costs are changing worldwide to get a better sense of these pressures.

Ready to stop guessing and start pricing for profit? TackonFSM gives you the tools to build a digital pricebook, create accurate estimates in minutes, and enforce your margins on every job. Ditch the spreadsheets and manage your entire electrical business from one powerful platform.