Electrical installation costs: A Practical Guide to Profitable Pricing

Figuring out electrical installation costs isn't rocket science, but it does require a solid foundation. Every accurate quote you build rests on three core components. Think of it like a three-legged stool: labor, materials, and overhead. Get one of those legs wrong, and the whole thing gets wobbly. Nailing how these pieces fit together is the key to creating quotes that land you the job and keep your business in the black.

The Three Pillars of Electrical Installation Costs

Smart pricing isn't a shot in the dark; it's a calculated process. When you hand a customer a quote, you're balancing these three fundamental elements to hit a number that’s fair for them but also sustainable for you. If you miscalculate any one of them, you’re putting the entire job’s profitability on the line.

It’s just like building a house. You wouldn't just charge for the lumber and nails. You’d also have to cover the carpenters' time and all the background costs of running a construction business. Electrical work is the exact same. The final price on that invoice is about a whole lot more than just the wire hidden in the walls.

Let's quickly take a look at what each of these cost components covers. Here's a table that breaks down the fundamentals every electrical contractor needs to account for when building an estimate.

Quick View of Electrical Installation Cost Drivers

| Cost Component | What It Covers | Impact on Final Price |

|---|---|---|

| Labor Costs | Wages, benefits, and taxes for every technician on the job. | Varies based on the experience level of the electrician and the total hours required. |

| Material Costs | All physical parts: wire, conduit, breakers, outlets, fixtures, etc. | Fluctuates with market prices, supply chain issues, and the quality of components chosen. |

| Overhead & Profit | The "cost of doing business": insurance, vehicles, tools, software, office rent, and your profit margin. | A crucial percentage added to every job to keep the business running and growing. |

Understanding these drivers is the first step. If you miss one, you're not just losing money on one job—you're threatening the long-term health of your entire business.

Deconstructing the Quote

Let's dig into what each of these pillars really means for your bottom line. Getting this framework right is what separates the pros who price strategically from those who are just guessing.

- Labor: This isn't just an hourly rate. It’s the cost of expertise. You're covering wages for everyone from the green apprentice to the seasoned master electrician, plus benefits and payroll taxes. This is what you charge for the skill and time it takes to do the job safely and correctly.

- Materials: This bucket includes every single physical item needed for the installation. We're talking wire, conduit, outlets, switches, breakers, panels, and light fixtures. It also has to account for the time spent sourcing parts and the reality of fluctuating market prices.

- Overhead and Profit: These are the unsung heroes of your quote. Overhead covers all the costs of keeping the lights on—your van insurance, gas, tool maintenance, liability insurance, software subscriptions, and office staff. Your profit margin is the money left over that allows you to invest back into the business and actually grow.

An accurate quote is more than just a price; it’s a promise. By properly accounting for labor, materials, and overhead, you’re showing the customer you can deliver safe, reliable work while building a healthy business that will be around to stand by that work for years to come.

This three-part structure is the bedrock of every estimate you'll ever write, whether it's for swapping a single outlet or wiring an entire commercial building. Mastering this formula turns quoting from a stressful guessing game into a repeatable, data-driven process that protects your margins on every single job.

Calculating Your True Labor and Material Costs

To build a quote that actually protects your profit, you have to look beyond the obvious numbers on a supply house invoice. The true costs of any electrical installation are often hidden just beneath the surface, tangled up in the details of your labor and the ever-changing materials market. If you’re just charging a flat hourly rate and marking up parts, you're almost certainly leaving money on the table.

Think about it this way: your labor rate isn't just what you pay an electrician per hour. It's a fully loaded cost that covers their years of expertise, their efficiency on the job, and the entire support system that allows them to work safely and effectively. In the same way, the price of a roll of Romex isn't just its sticker price; it includes the time spent getting it and the risk that it'll cost more next week.

The Real Cost of Labor on the Job

The biggest mistake I see contractors make is treating all labor as if it costs the same. It doesn't. The skill level of the technician you assign to a job has a massive impact on your bottom line, affecting both your direct costs and the final quality of the work. A master electrician costs more per hour, but they can solve a complex problem in a fraction of the time it would take an apprentice, saving you money in the end.

A single project might require a mix of different skill sets, each with its own cost:

- Apprentice Electrician: Perfect for assisting with the basics, like pulling wire or mounting boxes. Their lower hourly rate is key to keeping costs down on the labor-heavy parts of a job.

- Journeyman Electrician: These are the workhorses of most projects. A good journeyman can handle the bulk of installation tasks on their own, offering a great balance between high skill and a reasonable cost.

- Master Electrician: You bring in a master for the really tricky stuff—complex troubleshooting, final inspections, or overseeing a big crew. Their high cost reflects a deep well of experience that prevents costly mistakes and ensures everything is up to code.

On top of that, the union vs. non-union dynamic adds another layer. Union electricians often come with standardized wages and benefits. This can mean higher upfront labor costs, but it also provides a predictable level of skill. Non-union shops have more flexibility on pay but need to be diligent about their own training to maintain quality.

Uncovering Hidden Material Expenses

The price you see for materials like copper wire, breakers, and light fixtures is just where the costs begin. Every single part you order has "soft costs" attached to it, and if you don't account for them, your profit margin will get eaten alive.

Think about the real journey of a single circuit breaker. It doesn't just appear on the job site. Someone has to spend administrative time sourcing and ordering it. Then it has to be stored, either in the shop or on a van, taking up space. If it's a specialty item, you're probably paying for shipping, too.

The price of copper, a fundamental component in our trade, can swing wildly from one day to the next based on global markets. A quote that looked profitable on Monday could be a loser by Friday if you haven't built in a buffer for that volatility.

This is exactly why accurate material management is so crucial. It’s not just about knowing what you have in stock; it’s about understanding the total cost of getting every single part to the job. When you build these easily overlooked expenses into your pricing, you create a shield against market shifts and logistical headaches. For more ideas on building smarter quotes, check out these tips to simplify estimates and invoicing.

Accounting for Permits and Inspections

Finally, never, ever underestimate the cost and time tied up in dealing with the local building department. These aren't optional add-ons; they are mandatory expenses that have to be baked into your price from the very beginning.

- Permit Fees: Every municipality charges for permits to make sure work is done to code. These fees can be less than $100 for a simple panel swap or run into thousands for a large commercial build-out.

- Inspection Costs: Once the work is done, an inspector has to sign off on it. That involves scheduling the visit, meeting them on-site, and potentially making changes they ask for—all of which is time you need to bill for.

- Insurance and Bonding: Your liability insurance and bonds are non-negotiable protections. A small piece of those overhead costs has to be allocated to every single job you do.

By breaking down your labor, materials, and compliance costs with this level of detail, you stop guessing and start calculating. This granular approach is the only way to build bulletproof estimates that are fair to the customer and truly profitable for your business.

How Project Complexity and Location Shape Your Pricing

Every electrician knows that no two jobs are the same. A simple outlet installation in a new build is a completely different ballgame than a full service panel upgrade in a 100-year-old house. The difference in your electrical installation costs isn't just about the parts you use or the hours you log; it's about complexity, risk, and the stuff you can't see behind the walls.

Think of it like this: a simple job is a straight country road, but a complex project is a downtown freeway during rush hour. You've got on-ramps, off-ramps, and unexpected traffic jams. A standard job has a clear path, but a complex one forces you to navigate obstacles that can eat into your profit margin in a hurry.

Getting this assessment wrong is one of the fastest ways to lose money on a project. It’s the hidden surprises that always hit your bottom line the hardest.

Distinguishing Simple Jobs from Complex Nightmares

The scope of work is the most obvious thing separating an easy day from a tough one. Swapping a light fixture is predictable. Rewiring an entire commercial building? Not so much. The first you can probably quote over the phone, but the second demands a deep dive into blueprints, existing wiring, and potential roadblocks.

Let's break down two common jobs:

- Standard Outlet Installation: This is your bread and butter. You know the exact materials, you can estimate the time down to the minute, and the code requirements are second nature. Your costs are predictable, which makes it a low-risk, stable-profit job.

- Full Service Panel Upgrade: This kind of project is loaded with variables. You might open a wall and find ancient, non-compliant wiring, structural problems, or a main service line that’s shot. Every one of those discoveries adds time and material costs you couldn't have possibly planned for initially.

This is exactly why a thorough on-site visit is non-negotiable for anything more than a basic service call. It’s your chance to spot the risks, price the job right, and set clear expectations with the customer before you even touch a wire.

A great quote isn't just a number; it's a reflection of a well-understood project. By pricing for complexity, you're not just covering your costs—you're demonstrating your expertise and protecting your business from the unknown.

The Impact of Location and Macro Trends

Beyond the work itself, your physical location is a massive factor. Labor rates in downtown Manhattan are a world away from what they are in rural Montana. Local building codes can also change drastically from one county to the next, with some areas demanding more expensive materials or extra inspections.

Even getting to the job site can affect the price. A project on the 30th floor of a skyscraper with no parking will naturally have higher labor costs than a ground-floor job in the suburbs, just because of the logistical headache. You need a system that helps you manage these variables, which is why we put together this guide on field service scheduling software that saves time.

On top of all that, our industry is in the middle of some huge shifts. The electrical grid is set for a massive overhaul, with experts predicting over $1.4 trillion in spending by 2030 to modernize it. This is being fueled by the explosion of data centers and the push for industrial electrification. As a result, we're seeing lead times for critical parts like transformers stretch into years, which puts serious pressure on project timelines and costs. You can read more about these power and utility industry trends on deloitte.com.

This big-picture stuff really matters. A smart contractor keeps an eye on these macro trends to get ahead of material shortages, adjust pricing for higher demand, and position their business to grab a piece of the action.

Example Breakdowns of Common Electrical Jobs

Theory is one thing, but seeing how the numbers play out on a real job is what truly matters. Let’s walk through a few common projects every electrical contractor runs into. These examples give you a solid baseline for how labor, materials, and other fees come together to build a final, profitable quote.

Think of each job like a recipe. You have your ingredients (materials) and your cooking time (labor), but the final price always depends on the unique conditions of the kitchen you're working in.

Installing a 240V EV Charger

With electric vehicles becoming more common, installing Level 2 EV chargers is a huge part of the business now. The catch? The cost can swing wildly depending on the home’s existing electrical system.

A straightforward installation means running a new 240V dedicated circuit from the main panel to the garage or driveway. For a great deep-dive on this common modern upgrade, check out this guide on the cost to install an EV charger at home.

Here’s what a simple job might look like, assuming the panel has the capacity and is located nearby:

- Estimated Labor: 4-6 hours for one electrician. This covers working in the panel, running conduit, mounting the charger, and testing everything.

- Approximate Material Cost: $300 – $600. This includes a 40-50A double-pole breaker, 6-gauge copper wire, conduit, and fittings. It does not include the charger itself, which the homeowner almost always buys separately.

- Permits and Fees: $100 – $300, which varies based on what your local municipality requires for this kind of work.

- Total Estimated Project Cost: $800 – $1,700.

This range is just a starting point. If you have to run wire through finished walls, the panel is on the opposite side of the house, or you need to add a subpanel, the cost can easily double.

Main Circuit Breaker Panel Replacement

Swapping out an old or undersized electrical panel is a bread-and-butter job for any residential electrician. It’s a major safety upgrade that involves a ton of labor and careful coordination with the local utility company. The real work is in the meticulous process of disconnecting, removing, and re-wiring every single circuit in the house.

Here's how a standard 100A to 200A panel upgrade typically breaks down:

- Estimated Labor: 8-12 hours for a two-person team. This covers scheduling the power shutoff, doing the physical swap, labeling all circuits, and seeing it through inspection.

- Approximate Material Cost: $700 – $1,200. You're paying for the new 200A panel, a main breaker, all new circuit breakers (including AFCI/GFCI as required by code), and new service entrance cable and grounding components.

- Permits and Fees: $250 – $500. Panel upgrades are serious business, and the permit and inspection process reflects that.

- Total Estimated Project Cost: $2,500 – $4,500.

Wiring a Small Home Addition

When a homeowner builds an addition, they need you to handle the electrical from start to finish. Let’s imagine a simple 400-square-foot room that needs lights, outlets, and switches.

This kind of project is usually done in two trips: a rough-in before the drywall goes up, and a finish phase after.

- Estimated Labor: 16-24 hours total, split between both phases. This time is for planning the circuit layout, drilling studs, pulling wire, setting boxes, and then coming back to install all the devices and fixtures.

- Approximate Material Cost: $800 – $1,500. This budget should cover your Romex, boxes, switches, receptacles, recessed lighting cans, and smoke detectors. It typically doesn't include the decorative fixtures.

- Permits and Fees: $200 – $400, since you're adding new circuits and will need both a rough-in and a final inspection.

- Total Estimated Project Cost: $2,800 – $5,000.

To see how these components stack up side-by-side, let's put them into a clear table.

Sample Project Cost Estimates for Contractors

Here's a look at estimated cost ranges for typical electrical jobs, showing how labor, materials, and fees contribute to the final price.

| Project Example | Estimated Labor Hours | Approximate Material Cost | Permits and Other Fees | Total Estimated Project Cost |

|---|---|---|---|---|

| EV Charger Installation | 4 – 6 hours | $300 – $600 | $100 – $300 | $800 – $1,700 |

| Panel Upgrade (100A to 200A) | 8 – 12 hours | $700 – $1,200 | $250 – $500 | $2,500 – $4,500 |

| Wiring a Small Addition | 16 – 24 hours | $800 – $1,500 | $200 – $400 | $2,800 – $5,000 |

As you can see, even though the jobs are very different, the core formula for quoting them is the same. By consistently breaking down your labor, materials, and overhead for every single job, you build accurate quotes you can stand behind—and that keep your business profitable.

Protecting Your Profit Margins with FSM Software

Knowing your costs is only half the battle. The other, more critical half is actively protecting your profit margins on every single job. For too long, electrical contractors have been stuck using manual quoting methods, outdated spreadsheets with inconsistent pricing, and the constant headache of watching margins get squeezed. This old way of doing things leaves you wide open to surprise costs and lost income.

It's time to move from guesswork to a system built on real data. Field service management (FSM) software was designed to solve this exact problem, turning the difficult art of estimating into a repeatable, reliable science. It becomes the command center for your entire operation, making sure every quote you send is fast, accurate, and profitable from the moment you build it.

Building Bulletproof Quotes with Dynamic Pricebooks

At the heart of a good FSM system is an estimating tool powered by a dynamic pricebook. Instead of wasting time digging through old invoices or calling a supply house for current pricing, your team can put together a detailed estimate in minutes. All your parts and labor rates are pre-loaded and up-to-date.

Think of it as a digital catalog of every single component you use—from breakers and outlets to wire nuts and conduit—with your current costs and preferred markup already built in. This is exactly what a tool like TackonFSM delivers.

- Speed and Consistency: Your techs can build quotes right on-site from a tablet or phone, ensuring every estimate looks professional and uses the same pricing rules.

- Accuracy: Say goodbye to typos and forgotten line items. The system makes sure every part and every minute of labor is accounted for.

- Professionalism: You'll send clients clear, itemized quotes that build trust and show them exactly where their money is going.

The goal here isn't just to cover your costs. A powerful FSM tool actively enforces profitability by building your desired margin into the structure of every estimate. This guarantees every job you win is actually making you money.

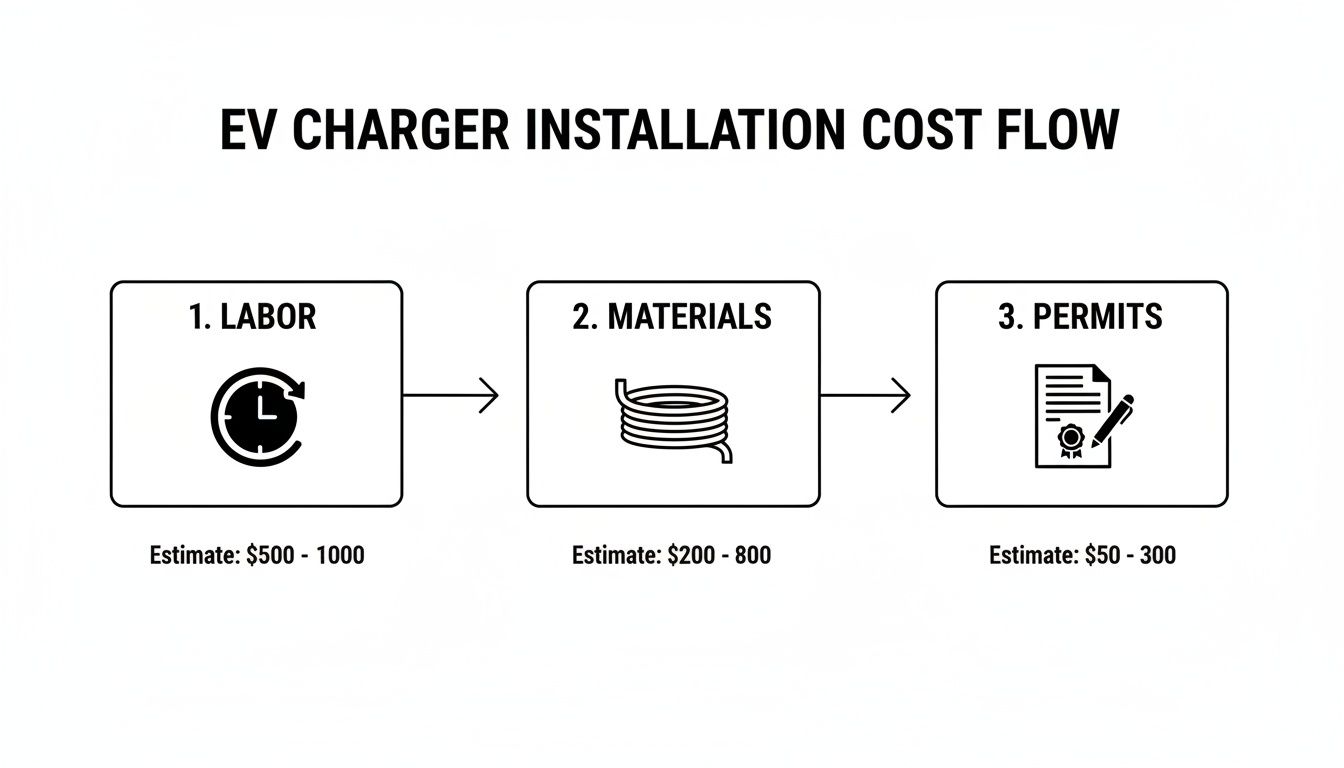

This diagram shows how the core components—labor, materials, and permits—come together when estimating a common job like an EV charger installation.

This is the exact process that modern software automates, allowing you to create accurate quotes consistently and at scale.

From Reactive Estimates to Proactive Profitability

A truly great FSM platform doesn't just help you quote faster; it helps you quote smarter. Features like automated markup rules and minimum margin enforcement act as your financial safety net. For instance, you can set a rule that automatically applies a 30% markup on all materials or flags any quote that falls below a 25% gross margin. This puts you in control, ensuring profitability before your team even leaves the shop.

This is especially important in today's market. With soaring global electricity prices, your own operational expenses are on the rise, from powering tools to fueling your trucks. For contractors using a tool like TackonFSM, this volatility makes the built-in estimating features invaluable. You can apply markups and enforce minimum margins on every job, while the real-time inventory from the Elastic Parts Database (with over 3,000 items) prevents over-ordering. This is how you stay ahead.

Choosing the right software is a big decision that can have a major impact on your bottom line. To see how different options stack up, a comprehensive Field Service Management (FSM) software comparison can be an incredibly helpful resource.

Connecting the Field to the Office

The real power of FSM software comes from connecting your entire workflow, from the initial quote all the way to the final invoice. This integration saves countless hours of administrative work and plugs the financial leaks that drain your profits.

- Estimate to Job Conversion: Once a customer gives the green light, the quote converts into a scheduled job with one click. All the parts, labor hours, and special notes are transferred automatically.

- Real-Time Parts Tracking: When your technician uses a part on the job, it's immediately deducted from your inventory. This prevents running out of stock and, more importantly, ensures you bill for every single component you use.

- Job to Invoice Automation: As soon as the work is done, all the job data flows directly into a final invoice. This kills the tedious, error-prone task of re-entering everything, which means you get paid faster and more accurately.

This unified system gives you a crystal-clear picture of your company's financial health. You can see your company dashboard in TackonFSM and track everything from your quote approval rates to job-by-job profitability in real time. When you move away from disconnected spreadsheets and adopt an all-in-one platform, you’re no longer just managing jobs—you’re actively building a more profitable business.

Frequently Asked Questions About Pricing Electrical Work

As a contractor, you're not just selling your skills—you're also guiding your clients. Homeowners and business owners have plenty of good questions about electrical installation costs, and answering them clearly is one of the best ways to build trust and manage expectations.

Think of these questions as opportunities. When a client asks "why," they aren't just challenging your price; they're inviting you to prove your expertise. Here are some straightforward answers to the most common questions you'll get about your pricing.

How Do You Determine Your Hourly Rate for Electricians?

Our hourly rate is a lot more than just an electrician's wage. It's a fully-loaded number that covers everything it takes to get a skilled, insured, and well-equipped professional to your front door. We've carefully calculated it to include everything needed for a safe, high-quality job.

Beyond the technician's salary, that rate includes:

- Essential Overheads: This covers the nuts and bolts of running the business, like liability insurance, work vehicle maintenance, fuel, and the cost of thousands of dollars in specialized tools.

- Ongoing Training: We invest in continuous education to keep our team sharp on the latest electrical codes, safety protocols, and new technologies.

- Business Support: It also helps cover our office staff who manage scheduling, pull permits, and answer your calls.

The rate also reflects a technician's experience. A master electrician with two decades in the field will command a higher rate than a first-year apprentice, and that’s a good thing. It ensures you get the right expertise for your specific job while we run a healthy business that can stand behind our work for years to come.

Why Can Material Prices Change Between the Quote and the Job?

This is a really common concern, especially when the market is all over the place. The cost of materials, especially anything with copper like wiring and cables, is tied to global commodity prices that can change in a heartbeat. A supply chain hiccup, a spike in demand, or even international events can send prices climbing overnight.

We do our best to give you a solid, accurate quote using professional software with constantly updated price books. Our goal is to lock in a price for you that's fair and predictable.

A professional quote is a snapshot in time. We build our estimates using the best data available, but we also believe in being completely transparent. If we think certain materials for your project are at risk of a price swing, we'll let you know upfront and make a note of it in the proposal.

This way, there are no surprises. It’s all about creating a partnership based on clear communication right from the start.

What Is the Most Accurate Way to Quote an Electrical Job?

There's only one way to give a truly accurate, fixed-price quote: a detailed on-site assessment. We can sometimes give a ballpark estimate over the phone for simple jobs like swapping a switch, but anything more involved needs a professional's eyes on the situation. A visual inspection is absolutely critical to understanding the real scope of the work.

An on-site visit allows our electricians to:

- Spot Potential Roadblocks: We can see issues you’d never know about from a phone call, like old, crumbling wiring, tricky access points, or a main panel that's already maxed out.

- Take Precise Measurements: This ensures we calculate the exact amount of wire and conduit needed, which avoids waste and saves you money.

- Confirm Code Compliance: We can verify that the work we’re planning will meet all local electrical codes and pass inspection.

After that visit, we’ll draw up a detailed, itemized quote that breaks down every labor and material cost, line by line. This method protects both of us by creating a clear, documented plan and preventing unexpected charges later on.

How Can Contractors Control Costs Without Compromising Quality?

The secret to keeping costs in check without ever cutting corners is operational efficiency. We invest heavily in systems that cut down on wasted time, reduce administrative headaches, and prevent expensive mistakes. This is where modern field service management software makes a huge difference.

By using an integrated platform, we connect our entire workflow. We can optimize scheduling and dispatching so our techs show up on time with the right parts for that specific job. Our quoting process is standardized and accurate, which helps us avoid the kind of mid-job changes that blow up a budget.

This focus on running a tight ship means we can offer competitive pricing—not because we're using cheap materials, but because we've eliminated the hidden costs that come from disorganization. It lets us protect our margins without ever having to think about compromising the quality or safety of our work.

Ready to stop guessing on quotes and start protecting your profits? TackonFSM provides the tools you need to build accurate estimates, track every part, and manage your jobs from a single, easy-to-use platform. Discover how TackonFSM can streamline your business today.