Realtime Inventory Management for Trade Businesses

Think of real-time inventory management as a live, constantly updating count of every single part you own. Instead of doing a stock take every month and finding out what you should have ordered weeks ago, this approach uses technology to track your stock levels the second they change.

It replaces those outdated, time-consuming manual counts with a precise, moment-to-moment view of what's in the warehouse and on every truck. No more guesswork, no more costly surprises.

Your Live GPS for Every Part

Imagine trying to get around a big city using a paper map printed last year. You'd be stuck in traffic on roads that have since closed and completely miss the new, faster routes. Running an HVAC, plumbing, or electrical business with outdated inventory counts is pretty much the same thing.

Real-time inventory management is the live GPS for your business's parts.

When a technician pulls a condenser from their van for a repair, the system logs it and deducts it from their mobile inventory right then and there. When a fresh shipment of PVC pipes lands at the warehouse, a quick scan adds it to your company-wide count instantly. It’s that simple.

This isn't just a better way of counting parts. It's about having total, minute-by-minute control over the physical assets that your revenue and reputation depend on.

This creates a single, reliable source of information that everyone—from the dispatcher in the office to the apprentice in the field—can trust.

Moving from Guesswork to Certainty

The old way of tracking inventory is purely reactive. You count everything up at the end of the month, find out what you're short on, and then scramble to fix it. This approach creates a messy cycle of problems that eats into your profits. Real-time inventory management, on the other hand, is proactive.

With a live view of every part, you can see a problem developing long before it becomes an emergency. This shift brings some game-changing advantages:

- Instant Visibility: You know exactly what's on every truck and every warehouse shelf, right now. This puts an end to those frantic phone calls between the office and the field just to find a simple component.

- Automated Updates: As parts are used on jobs, moved between vans, or checked in from suppliers, the system updates on its own. This eliminates the human error that comes with scribbled notes and manual data entry.

- Smarter Purchasing: You can finally make buying decisions based on hard data and actual usage trends, not just a gut feeling. Stop tying up cash in parts that just sit there, and make sure you're always stocked with the essentials.

This change turns inventory from a constant headache into a real strategic advantage. When you know what you have and where it is at all times, you can finally solve some of the most expensive and frustrating problems in the trades—like surprise stockouts, time-wasting supply runs, and misplaced parts that wreck a job's profitability.

The True Cost of Inefficient Parts Tracking

Let's get real for a moment. The true conversation about inventory management isn't some high-level theory; it’s a story told on your profit and loss statement. When parts tracking is a mess, it’s not just an inconvenience. It’s a silent, steady drain on your company’s financial health, creating hidden costs that pile up with every single job.

Picture this: one of your best techs, Mark, is at a customer’s house, ready to wrap up a plumbing repair. Then he realizes he’s missing the one specific P-trap he needs. What happens next is a cascade of expensive problems.

Mark has to pack everything up, drive across town to a supply house, kill time waiting in line, and then drive all the way back. That single, unplanned trip can easily burn 90 minutes or more of billable time. Now, multiply that by a few technicians and several jobs a week. Suddenly, you're losing hundreds of productive hours every month.

The Domino Effect of Poor Stock Data

That wasted time is just the tip of the iceberg. The operational chaos that stems from inaccurate inventory data opens up several other financial leaks. They’re harder to spot, but they are just as damaging.

When your team can't trust the stock counts in the system (or on the clipboard), they create their own workarounds. Technicians start hoarding popular parts in their vans "just in case," tying up your cash in redundant, untracked inventory that sits there doing nothing.

This fundamental lack of reliable data hits your bottom line in a few other critical ways:

- Inaccurate Quoting: The office staff puts together a quote based on the parts they think are in stock. If a key component isn't actually there, you're stuck paying rush-order fees to get it, which instantly shrinks—or even completely wipes out—the job's profit margin.

- Unbilled Materials: Without a clear system connecting parts usage to invoicing, small but costly items constantly get left off the final bill. Those "forgotten" parts—a handful of fittings here, a specific valve there—can easily add up to thousands of dollars in lost revenue every year.

- Customer Dissatisfaction: Every delay and every return trip chips away at customer confidence. A simple repair that turns into a multi-day saga is a recipe for negative reviews and lost repeat business. That's a long-term cost that’s tough to quantify but impossible to ignore.

Inefficient inventory isn’t just about losing parts; it’s about losing time, profit, and customer trust. Each error compounds, turning small oversights into significant financial burdens.

This is precisely where the jump to realtime inventory management plugs the leaks for good. Studies have shown this shift can take stock accuracy from a shaky 76% with traditional methods to an impressive 98.7% accuracy rate when done right. For trade businesses, that leap prevents an average of $3,200 in monthly losses from stockouts alone. You can discover more about these real-world results and see how they are reshaping the industry.

From Financial Drain to Strategic Gain

When you flip the script from reactive chaos to proactive control, these losses are transformed into measurable wins. A real-time system gives you a single source of truth for every part, whether it's sitting in the main warehouse or bouncing around in a technician's van.

This clarity delivers an immediate return on your investment. Quotes are built with confidence because they’re based on live stock data, ensuring profitability from the get-go. Technicians show up at job sites fully equipped, which maximizes their billable hours and lets them complete more jobs each day.

Most importantly, every single part used is automatically logged against a job, making sure it gets included on the final invoice. Those thousands of dollars in unbilled materials no longer slip through the cracks; they go straight to your bottom line. By eliminating emergency supply runs, cutting down on unnecessary holding costs, and guaranteeing accurate billing, a modern system makes an undeniable business case for leaving outdated tracking methods in the past.

How to Implement Real-Time Inventory Management

Making the leap from clipboards and spreadsheets to a modern, real-time system can feel like a massive undertaking. The good news? It's far more manageable when you break it down into a clear, step-by-step process. A thoughtful plan is your best friend for a smooth, low-stress transition that gets your team on board and delivering results fast.

This isn't about flipping a switch overnight and changing everything at once. It’s about building a solid foundation, testing the process, and then scaling up with confidence.

Start With a Thorough Inventory Audit

Before you can build the new system, you need to be brutally honest about the old one. The first step is a complete audit of every part you own and every process you use. Think of it as getting a realistic picture of the chaos you’re trying to fix.

This goes way beyond just counting parts. You need to map out the entire journey a component takes in your business, from the moment a purchase order is placed to when it’s installed at a customer’s site.

Your audit should answer a few critical questions:

- Where is everything? Seriously, everything. Document every location, including the main shop, any secondary warehouses, and every single technician's van.

- What are the biggest headaches? Talk to your team. Find out what frustrates them most about finding and using parts. Is it inaccurate counts? Messy vans? Constant trips to the supply house?

- How are parts actually tracked now? Dig into the informal systems—the handwritten notes on invoices, the text messages between techs and the office, the sticky notes on monitors.

This deep dive gives you an essential baseline. You’ll know exactly what problems your new real-time inventory management system needs to solve, which makes picking the right software and measuring your success down the road so much easier.

Select the Right Software for Your Trade

Once you’ve got a handle on your needs, it's time to choose your technology partner. This is a crucial step. Generic, off-the-shelf inventory software often falls flat for trade businesses because it isn't built for the unique challenge of managing mobile inventory across a fleet of vehicles.

Look for a field service management (FSM) platform with inventory control baked into its core, not just tacked on as an afterthought. This is non-negotiable. It ensures that tracking parts is seamlessly connected to everything else you do—scheduling, quoting, and invoicing.

Choosing the right software is less about finding the most features and more about finding the best fit for your daily workflow, both in the office and out in the field.

A powerful system also gives you a bird's-eye view of your mobile assets. To really tighten up your operations and get live visibility, many businesses look into tools like Fleet Tracking Systems, which often integrate with FSM platforms to give you a complete picture.

Run a Pilot Program and Train Your Team

With your software chosen, resist the temptation to go live across the whole company at once. That's a recipe for disaster. Instead, launch a pilot program with just one or two of your most tech-savvy technicians. Treat a single van as a mini-launch to work out all the kinks in a low-risk environment.

This pilot phase is where the magic happens. It allows you to:

- Refine Your Process: Test your new workflow for checking parts in and out, updating stock levels from the field, and creating purchase orders. You’ll find little things you didn't think of.

- Gather Feedback: Your pilot techs will become your champions. Their firsthand feedback is gold—use it to adjust training materials and prepare for common questions before the full rollout.

- Build Confidence: A successful small-scale test proves the value of the new system to the rest of the team. Suddenly, they'll be excited about the change instead of dreading it.

Don't skimp on training. Focus on the "why" behind the change. Explain how it makes everyone's job easier by eliminating last-minute supply house runs and ensuring they always have the parts they need. Keep it practical with hands-on sessions and simple, easy-to-follow cheat sheets.

The push for this level of control is happening everywhere. The global inventory optimization market, valued at $5.87 billion in 2025, is projected to hit $12.42 billion by 2032. This explosive growth shows just how critical this technology has become for staying competitive. By following these steps, your business can make the same successful transition.

What to Look for in a Trade-Specific Inventory Platform

Picking an inventory platform isn't a one-size-fits-all game. The software that works for a retail store or an e-commerce warehouse just won't cut it for a trade business. Why? Because your inventory isn't sitting on a shelf in one building; it’s spread across a fleet of moving warehouses—your vans.

To really get a handle on your parts, you need a system built around the day-to-day realities of HVAC, plumbing, and electrical work. The right features can make the difference between a tool that simplifies your operations and one that just adds another layer of busywork. Think of this as your checklist for finding a system that actually fits.

The right platform is the backbone of effective realtime inventory management, turning parts chaos into a serious competitive advantage. Many of these systems borrow concepts from larger logistics operations, and understanding the core warehouse management system (WMS) benefits can highlight what features really drive efficiency and accuracy in the field.

Must-Have Feature: Multi-Location Tracking

If there’s one feature that’s absolutely critical for a trade business, it’s multi-location tracking. And I don't just mean tracking what's in your main shop. A truly powerful system lets you create and manage a separate inventory location for every single van in your fleet.

This means you can see, at a glance, that Van 7 has three condenser motors while Van 4 is down to its last one. That kind of visibility is a game-changer for dispatching. Instead of sending a tech to a job hoping for the best, you can assign the one whose truck is already stocked with the right parts, saving a ton of time and fuel.

A system that can’t track inventory down to the van level isn’t built for the trades. It’s a non-negotiable feature that directly impacts your team’s daily efficiency and first-time fix rates.

Mobile App Access with Barcode Scanning

Let's be honest: your technicians are the ones on the front lines of your inventory system. If using it is a pain—requiring them to pull out a laptop or navigate a clunky interface—they just won't do it. A clean, intuitive mobile app isn't a nice-to-have; it's essential for getting your team on board and keeping your data accurate.

The app has to make it dead simple for techs to log parts they use right from the job site. The gold standard here is integrated barcode and QR code scanning. A quick scan with their phone's camera is all it should take to pull a part from their van's inventory and tie it directly to the work order. This one simple action practically eliminates manual entry errors and ensures every single part is accounted for and, most importantly, billed for.

Automation and Integration Capabilities

A great inventory platform doesn't live on an island. It needs to talk to the other critical software you use to run your business. This is what turns a simple parts list into a powerful operational hub.

Here are the key connections you should be looking for:

- Automated Low-Stock Alerts: The system should automatically ping you when a part—either in the main warehouse or on a specific van—dips below a level you set. This shifts your purchasing from a reactive scramble to a proactive, data-driven process.

- Integrated Purchase Orders: When you get a low-stock alert, you should be able to create and send a purchase order to your supplier right from the platform. It closes the loop and prevents critical parts from falling through the cracks.

- Job and Invoicing Sync: This is where the money is. When a tech scans a part and adds it to a job, that information must flow automatically to the final invoice. This direct link between field usage and billing is what stops thousands of dollars in parts from vanishing into thin air each year.

By focusing on these trade-specific features, you can find a realtime inventory management platform that actually supports your business—empowering your team to work smarter, protecting your profit margins, and helping you deliver a better experience for your customers.

See How TackonFSM Makes It All Work

Knowing the theory behind real-time inventory management is great, but actually making it happen in a busy shop is a whole different ballgame. That’s where a tool built specifically for the trades becomes a game-changer. TackonFSM was designed from the ground up to solve the exact inventory headaches that HVAC, plumbing, and electrical contractors deal with every single day.

Forget trying to wrestle with generic software that wasn't made for you. TackonFSM gives you a connected system that links the office, the warehouse, and every single truck on the road. It takes the complex idea of inventory control and turns it into a simple, practical workflow that actually protects your bottom line and helps your team get the job done right.

Get Up and Running in Hours, Not Weeks

Let's be honest, one of the biggest reasons owners put off new software is the nightmare of building a parts database. Who has time to manually enter thousands of parts, descriptions, and prices? That’s hundreds of hours you just don’t have. TackonFSM gets rid of that roadblock with its pre-loaded Elastic Parts Database.

The moment you log in, you have a shared pricebook with over 3,000 common HVAC, plumbing, and electrical parts already waiting for you. This means your system is instantly populated with the items your crew already uses, so you can start building accurate quotes and tracking stock from day one. And as you add your own unique parts, the database just gets smarter, creating a go-to resource for the whole company.

The Life of a Part in TackonFSM

To really see how this plays out, let’s follow a single component—say, a standard capacitor—on its journey through the TackonFSM system. This simple example shows how real-time inventory management becomes a natural part of your daily routine.

- Ordering and Receiving: The office manager gets an alert that warehouse stock on that capacitor is low. Right from TackonFSM, they create a purchase order and shoot it over to the supplier. When the box arrives, a quick scan of the barcode adds the new parts to the main warehouse count.

- Stocking a Van: A tech, let's call him Alex, needs to stock his van for the week. He requests five capacitors. Using the mobile app, the warehouse manager transfers those five parts, which instantly subtracts them from the warehouse and adds them to Alex's specific truck inventory.

- Using a Part on the Job: Out on a service call, Alex finds a bad capacitor. He grabs a new one from his van, scans it with his phone, and adds it directly to the work order. Just like that, TackonFSM deducts the part from his van’s stock and assigns it to that specific job.

- Invoicing for Every Penny: Back in the office, the dispatcher sees the job is done. When they create the invoice, that capacitor—with the correct price and markup—is already on the list. The part gets billed, and you’ve captured that revenue instead of letting it slip through the cracks.

This closed-loop process means you have eyes on a part from the moment it enters your shop to the moment a customer pays for it. It completely eliminates the blind spots where parts get lost, used but never billed, or reordered when you already had plenty.

A Solution That Grows With You

Whether you’re a two-person crew or running a fleet of twenty vans, a powerful inventory system should be within reach. TackonFSM was built with scalable plans that make sense for your business, no matter the size. For smaller teams, you can start with affordable core features like professional quoting and scheduling, then add inventory management when you’re ready.

As you grow, you can easily move up to plans that include the full suite of field and warehouse inventory tools without a massive price hike. This way, you only pay for what you need, making true real-time inventory management a practical tool for any trade business. When your system makes tracking this simple for everyone, you can finally get a real handle on your parts, protect your margins, and get back to focusing on great service.

Frequently Asked Questions About Realtime Inventory Management

Switching to a new system, especially for something as critical as inventory, naturally brings up a lot of questions. You need real answers that address the day-to-day headaches you actually face in the field. This FAQ is here to tackle the most common concerns we hear from HVAC, plumbing, and electrical business owners thinking about making the move to real-time inventory management.

Let’s cut through the fluff and get straight to what this change means for your team, your budget, and your bottom line.

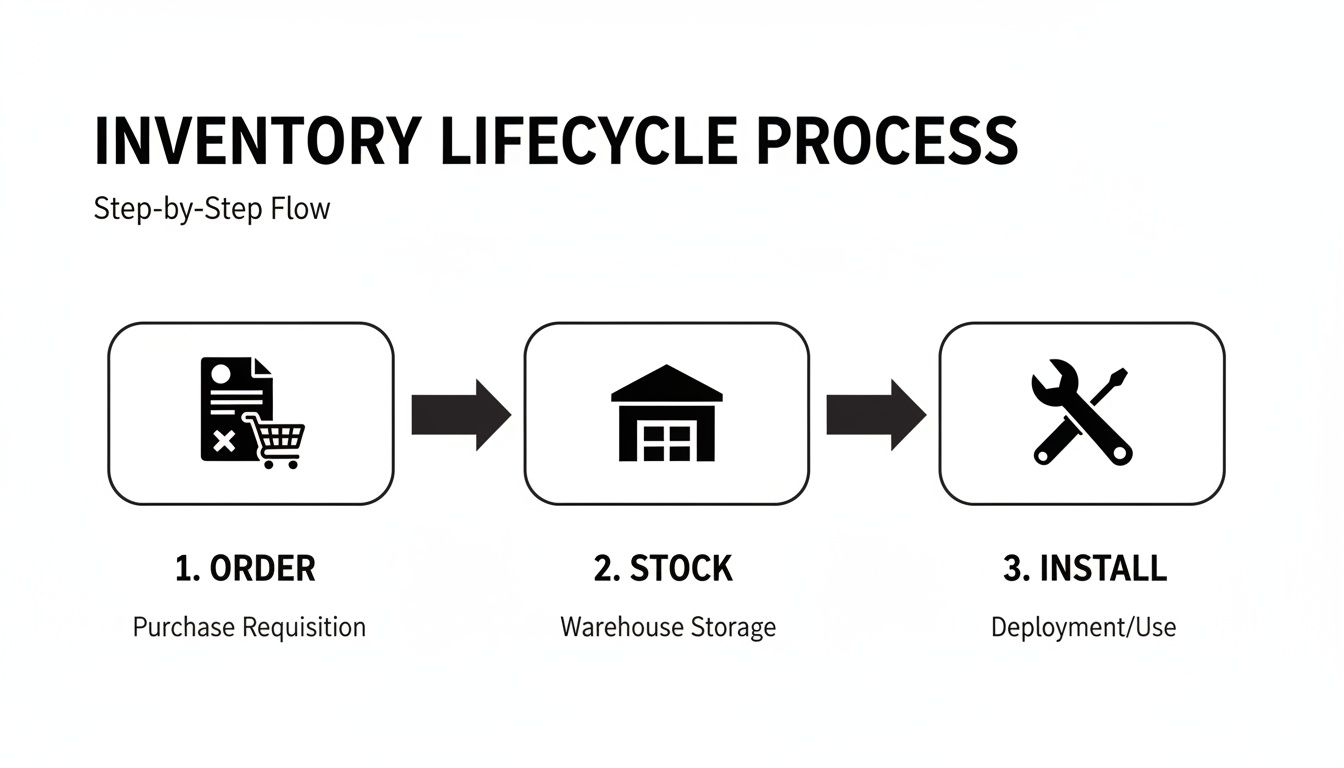

A good way to visualize this is to see the simple journey a part takes in a real-time system.

This diagram shows how every step is connected, giving you a clear, unbroken line of sight from the moment a part is purchased to the moment it’s installed.

Will This Actually Work for My Mobile Team?

This is usually the first—and most critical—question. The answer is a definite yes, but only if you choose a system that was actually built for the trades. The problem with generic inventory software is that it sees your vans as just a bunch of shelves in one big warehouse, which couldn't be further from reality.

A true field service platform understands that each van is its own moving stockroom. It empowers your techs to log parts usage right from their phone or tablet the second they pull it from the truck. The secret sauce is a simple mobile app, often with barcode scanning, that makes updating inventory as easy as snapping a picture.

How Much Training Does My Team Need?

Honestly, the learning curve is probably a lot less steep than you're picturing. Today’s platforms are built to be intuitive, especially the mobile apps your techs will be using. If they can navigate a smartphone, they can learn to manage their van stock with just a few taps.

The best training doesn't just show them how to use the tool; it explains why it helps them. Once your crew realizes the new system means fewer last-minute runs to the supply house and way less paperwork, they'll get on board pretty quickly.

A smart rollout usually involves:

- A small pilot program with one or two trusted techs to iron out any wrinkles.

- Simple how-to guides or short video tutorials they can watch on their phones.

- Reliable support to answer questions as they come up in the first few weeks.

The point isn’t to turn your expert technicians into data-entry clerks. It’s to give them a tool that makes their lives easier by making sure they have what they need to finish the job on the first visit.

When you frame it that way, inventory management stops being a chore and becomes a key part of a smoother, more satisfying workday.

Is This Affordable for a Small Business?

It’s a common myth that real-time inventory management is a high-priced luxury for massive, enterprise-level companies. A decade ago, that might have been the case. Today, the technology is well within reach for businesses of all sizes.

Modern software-as-a-service (SaaS) platforms work on a subscription basis. This gets rid of the huge upfront cost of buying servers or custom-built software. Instead, you pay a predictable monthly fee that grows as your team grows. For a small business, this means you can start with the essential features you need now and add more powerful tools later on.

Think about what it’s costing you to not have a system like this:

- Lost Parts: Thousands of dollars in materials that are used but never billed for.

- Wasted Labor: Countless technician hours burned on extra trips to the supply house.

- Shrinking Margins: Rush order fees and inaccurate quotes that slowly chip away at your profit.

When you compare those ongoing losses to a monthly subscription fee, the return on your investment becomes obvious—and fast.

What Is the Biggest Benefit I Will See First?

While the long-term gains are significant, the change you'll feel almost immediately is a massive reduction in wasted time. Those frantic calls between the office and the field trying to track down a specific part? They practically vanish.

Your dispatcher can see exactly which van has the parts needed for an emergency call, allowing them to send the right tech the first time. Your technicians stop burning billable hours driving back and forth to the shop and can instead fit more jobs into their day. This boost in pure operational efficiency hits your bottom line almost instantly.

Ultimately, real-time inventory management gives you a command and control over your business that just wasn't possible before. It plugs the financial leaks, helps your team work smarter, and builds a more resilient, profitable company.

Ready to stop guessing and start knowing exactly where your parts are? TackonFSM provides the tools you need to take full control of your inventory, from the warehouse to every van in your fleet. See how our trade-specific platform can protect your profits and streamline your operations. Start your free trial today.