A Guide to Estimating for HVAC

Getting your HVAC estimates right is more than just a task—it's the absolute foundation of a profitable business. It's how you stop guessing and start building a real strategy, accurately figuring out materials, labor, overhead, and profit to create bids that actually win jobs and protect your bottom line.

Why Accurate HVAC Estimating Matters

The moment you move beyond back-of-the-napkin math is the moment you start building a truly successful HVAC company. An estimate isn't just a price you hand a customer; think of it as a detailed financial roadmap for the entire project. When you get it right, you set clear expectations, build trust, and make sure your cash flow stays healthy.

Inaccurate estimates, on the other hand, create a domino effect of problems. If you bid too low, you might land the job, but you’ll likely end up rushing, cutting corners, and maybe even losing money. Bid too high, and you're just handing work over to your competitors. Finding that profitable sweet spot is all about precision.

The Strategic Foundation of Your Business

Every estimate you send out is a promise. It’s a promise to your customer about the quality and cost, and it's a promise to yourself that the job will actually be profitable. This process is the financial engine that keeps your whole operation running.

A solid, well-thought-out estimate has a direct impact on the most important parts of your business:

- Financial Health: It ensures every single job contributes positively to your revenue and covers all your costs, both on-site and off.

- Project Management: It gives your team a clear budget and scope of work, helping them manage time and materials effectively without constant guesswork.

- Customer Trust: A detailed, professional proposal shows you’ve done your homework. It justifies your pricing and builds the client's confidence in your ability to deliver.

- Business Growth: Consistently profitable jobs generate the capital you need to invest back into the business—for better tools, more training, or even expansion.

This kind of disciplined approach is non-negotiable in an industry that's growing like ours. The global HVAC systems market was valued at around USD 241.52 billion in 2024 and is expected to hit USD 445.73 billion by 2033. In a competitive market like that, accuracy and efficiency are what separate the best from the rest. You can dig into more data on the expanding HVAC market to see just how fast things are moving.

Key Takeaway: An estimate isn't just about adding up costs. It’s about strategically planning for profit on every single project to ensure the long-term health and reputation of your company.

Core Components of a Winning Bid

Every winning HVAC estimate is built on four fundamental pillars. You have to get these right—it's non-negotiable if you want to create bids that are both competitive and profitable. Skimp on any one of these, and you can watch your profit margin evaporate.

Think of these as the building blocks that make up your total project cost:

- Materials: This is the obvious one—the furnace, the AC unit, the heat pump. But it’s also all the supporting parts: the ductwork, wiring, coolant, fasteners, and every other small piece needed to do the job right.

- Labor: This is your crew's time on the job. Crucially, this must be based on a fully burdened labor rate. That means you're accounting not just for their hourly wage but also for payroll taxes, insurance, and benefits.

- Overhead: These are all the hidden costs of just keeping the lights on. We're talking about rent for your shop, vehicle maintenance, marketing expenses, office salaries, and software subscriptions.

- Profit: This is what’s left after every other bill is paid. It's not a dirty word; it's the money that allows your business to survive, grow, and thrive.

Mastering how to quantify these four elements is the real secret to effective estimating for HVAC services. When you shift your mindset from just quoting a price to strategically planning for profit, you set your business up for success that lasts.

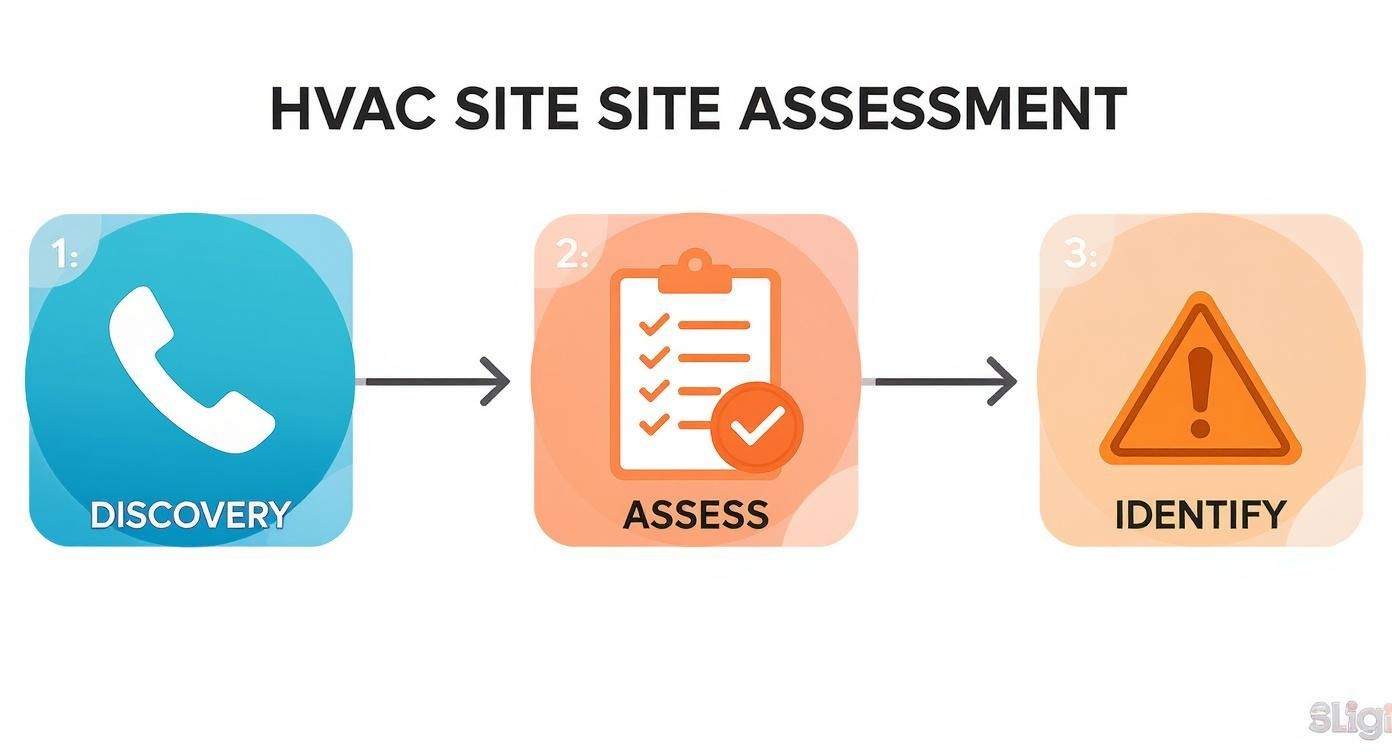

The Site Assessment: Where Great Estimates Begin

The most accurate estimates don't start with a spreadsheet. They start with a conversation and a keen eye. The real secret to nailing your estimating for hvac projects lies in the details you pull from that initial client call and how thoroughly you inspect the property. This is where you move past the competition by truly understanding what the job requires.

It all kicks off with that first phone call or email. Your goal is more than just booking an appointment; it's to start digging into what the client really needs. A homeowner might say, "I need a new AC," but what they often mean is, "My energy bills are killing me," or "The master bedroom feels like a sauna." Asking smart questions right away shifts you from a simple order-taker to a trusted problem-solver.

These early chats are also the perfect time to gently get a feel for their budget and timeline. It's a simple step that prevents you from designing a top-of-the-line system for a client who can only afford a mid-range option, saving everyone a major headache.

Nailing the Client Discovery Call

That first interaction really sets the stage. Don't just tick boxes and collect an address—guide the conversation to uncover the real reasons they called you.

A well-handled discovery call pays off in a few key ways:

- You find the root cause: Is it just a dead compressor, or is the whole system poorly designed for the house?

- You define the real scope: This helps you figure out if you're looking at a simple unit swap or a major retrofit that involves new ductwork.

- You start building trust: When you listen intently, you show the client you’re focused on the right solution, not just a fast sale.

Get past the technical talk for a moment. Ask questions that reveal their actual comfort and efficiency worries. A simple question like, "Are there any rooms that are always too hot or too cold?" can expose ductwork or insulation problems that a new furnace alone will never fix.

Mastering the On-Site Walkthrough

Once you’re on-site, put on your detective hat. You're searching for clues about the current system, the home’s layout, and any hidden roadblocks that will add time and money to the job. A rushed walkthrough is the fastest way to an unprofitable project.

Be methodical. Your inspection needs to cover every single thing that could affect the HVAC system's installation and performance. We're talking about everything from the electrical panel's capacity to how you'll physically get the new equipment into a tight basement. Don't just glance at the old unit; analyze the entire environment it lives in.

Your site assessment is the best insurance policy you have against surprise costs. What you find in that first hour can be the difference between a profitable job and one you wish you’d never taken.

This detailed inspection helps you spot the landmines before you step on them. In an older home, for instance, you might find an ancient electrical panel that can't handle a modern, high-efficiency system. Or you could discover the existing ductwork is undersized and leaking like a sieve, which would completely undermine the performance of a brand-new unit. These are the details that make or break your estimate.

Essential Site Assessment Checklist

Using a systematic approach means nothing gets missed. While every house has its quirks, a good checklist ensures you document the essentials and spot the red flags that will directly impact your numbers.

Here’s a look at what should be on your radar during every walkthrough.

| Area of Inspection | Key Items to Check | Potential Red Flags |

|---|---|---|

| Existing Equipment | Unit model, age, size (tonnage), refrigerant type, and general condition. | Obsolete refrigerant (R-22), signs of corrosion or leaks, mismatched indoor/outdoor units. |

| Ductwork System | Material (metal, flex), insulation level, visible damage, sealing at joints. | Kinked or crushed flex ducts, inadequate insulation, signs of mold or moisture. |

| Electrical System | Panel capacity, available breaker space, wire gauge to the existing unit. | Outdated fuse boxes, undersized wiring, aluminum wiring, overloaded circuits. |

| Insulation & Air Sealing | Attic and wall insulation levels, window quality, noticeable drafts. | Minimal or settled attic insulation, single-pane windows, visible gaps around doors. |

| Building Structure | Access points for equipment (doors, stairs), potential for asbestos or lead paint. | Narrow hallways, tight attic access, "popcorn" ceilings or old insulation that may contain asbestos. |

Taking photos and detailed notes of these findings is non-negotiable. This isn't just for your records; it's proof you can show the homeowner to explain why certain upgrades or repairs are necessary. It turns your bid from a price tag into a well-thought-out solution. This meticulous upfront work prevents those dreaded mid-job surprises and change orders, cementing your reputation as a true pro.

Calculating Material and Labor Costs

Now that you’ve done your homework on-site, it’s time to turn those notes and measurements into actual dollars and cents. This is where the rubber meets the road. Getting your material and labor costs right is the absolute foundation of a profitable HVAC estimate, as they are easily the biggest expenses on any given project.

Precision here isn’t just about protecting your bottom line; it’s about building trust with your customers. The U.S. HVAC market was valued at a whopping $30.41 billion in 2023, and with a projected 7.4% annual growth, the stakes are only getting higher. This growth is driven by today's complex, high-efficiency systems, which means our estimates have to be more detailed than ever. It's a big industry—U.S. consumers spend over $10 billion a year on HVAC services—and accuracy is your key to getting your fair share. For a deeper dive into market trends, check out these HVAC industry statistics from Workyard.com.

Building Your Material Cost List

Your materials list needs to be more than just the big-ticket items like the furnace or condenser. Think of it as a complete recipe for the job—every single nut, bolt, and fitting matters. I’ve seen too many contractors let their profits get eaten away by nickel-and-dime items they forgot to include.

A truly thorough material list always covers:

- Major Equipment: The furnace, AC unit, heat pump, or air handler itself.

- Supporting Components: Line sets, evaporator coils, filter housings, and plenums.

- Installation Supplies: Sealant, mastic, fasteners, electrical wiring, condensate pumps, and all the necessary PVC piping.

- Safety and Finishing: Thermostats, disconnect boxes, and pads for the outdoor units.

The infographic below shows how the initial steps of discovery and assessment directly feed into this calculation phase.

This logical flow—from the first call to identifying the exact issues on-site—is what gives you all the details you need to build an accurate material and labor breakdown.

To keep this from becoming a logistical nightmare, a dynamic price book is your best friend. Instead of manually looking up costs for every component on every job, a price book stores all your items and their current prices. Better yet, when it's built into field service software like TackonFSM, it ensures your estimates reflect what you're paying your suppliers today, not six months ago.

Pro Tip: I always add a 5-10% contingency to my total material cost for waste and incidentals. It’s just a fact of life in the field: a fitting will get dropped, a screw will go missing, or you'll need just a bit more refrigerant than you thought. This small buffer protects your profit from those little surprises that always seem to pop up.

Quantifying Labor Hours Accurately

Estimating labor is definitely part art, part science. You’ll never predict every single snag, but with a good system, you can get incredibly close. Just throwing a flat-rate number at every installation is a surefire way to lose money, because no two job sites are the same.

A great place to start is with industry time guides, like the ones published by the ACCA (Air Conditioning Contractors of America). These guides give you standardized labor hours for thousands of common HVAC tasks, assuming ideal conditions. Consider this your baseline.

From there, you have to adjust that baseline using the specific details you gathered during your site assessment.

- Access Issues: Is the unit stuffed into a cramped attic or a nasty crawl space? I’d add 15-25% more time right off the bat.

- Team Experience: Are you sending a senior tech who’s done this a hundred times, or a greener apprentice? Be honest and adjust the hours.

- Older Homes: Working with old plaster walls or funky, outdated wiring? That’s going to slow things down.

- Custom Fabrication: Does the job require custom sheet metal transitions? Don't forget to add in that shop time.

For instance, if the book says a furnace swap is an 8-hour job, but it’s in a century-old house with terrible access, you should probably budget 10 or 11 hours to be realistic and safe.

Calculating Your Fully Burdened Labor Rate

Once you have the hours, you need to multiply them by the right rate. This is where so many contractors go wrong. They just use their technician's hourly wage, totally forgetting all the other costs tied to having that employee on the payroll. This is hands down one of the most common and costly mistakes in estimating for hvac.

Your fully burdened labor rate is what it truly costs you for one hour of your tech's time. It’s not just their wage; it’s everything else that goes with it.

To figure it out, you need to add up:

- Hourly Wage: The technician's base pay.

- Payroll Taxes: FICA, federal, and state unemployment taxes.

- Workers' Compensation: The insurance premium to cover on-the-job injuries.

- Benefits: The cost of health insurance, retirement plans, and paid time off.

Let's say you pay a tech $30/hour. After you add payroll taxes (around 7.65%), workers' comp (let's use 5% for this example), and the cost of benefits (which could easily be another 20%), their actual cost isn't $30. It's closer to $39.79 per hour.

If you use $30 in your estimate, you’re losing almost $10 an hour right out of the gate, before you’ve even added a dime for overhead or profit. Calculating and using your fully burdened labor rate on every single estimate is non-negotiable if you want to run a profitable business.

Factoring in Overhead and Profit

https://www.youtube.com/embed/rD-l7kO4-F4

Alright, you've tallied up the costs for every part, fitting, and labor hour. But if you stop there, you're not running a business—you're running a charity. Just covering your direct costs is breaking even, and breaking even doesn't buy new trucks or keep the lights on.

This is where the real business acumen comes in: strategically adding your overhead and profit. Get this part of your estimating for hvac process right, and you build a sustainable company. Get it wrong, and you'll work yourself out of business.

Markup vs. Margin: A Critical Distinction

So many contractors get tripped up on the difference between markup and margin, often using the terms interchangeably. Trust me, this is a costly mistake that can silently bleed your profits dry.

Let's clear this up once and for all.

Markup is what you add to your cost to get the selling price. It's a simple, straightforward calculation.

Margin, on the other hand, is the percentage of the final sale price that is actual profit. It's the true indicator of how profitable a job really is.

Let's See it in Action:

Imagine a job costs you $1,000 in materials and labor.

- If you use a 50% markup, you add $500. The customer's price is $1,500.

- Your profit is $500. Now, to find your margin, you divide that profit by the sale price ($500 / $1,500). That gives you a 33.3% profit margin.

See the difference? A 50% markup is not a 50% margin. Confusing the two makes you think you're making way more money than you actually are. While markup is a quick way to build a price, margin is what you need to be watching to understand your financial health.

Calculating Your Company's Overhead

Before you can even think about profit, you have to cover your overhead. These are the relentless, everyday costs of just keeping your doors open—the expenses that hit your bank account whether you're on a job site or not. If you forget to bake these into every estimate, you’re literally paying for the privilege of working.

To figure out your overhead, you need to add up a full year's worth of indirect expenses:

- Your Shop & Office: Rent or mortgage payments.

- Your Fleet: Gas, insurance, maintenance, and truck payments.

- Your Team: Salaries for dispatchers, office staff, and yourself.

- Tools of the Trade: Phone and internet bills, plus software subscriptions like TackonFSM.

- The Essentials: Business liability insurance, workers' comp, and professional licenses.

- Getting the Word Out: Website costs, Google ads, and any other marketing you do.

Once you have that big annual number, you can break it down. A common method is to divide your total annual overhead by your total billable labor hours for the year. This gives you an "overhead cost per hour," a crucial number you must add to every labor hour just to cover your operating costs.

Strategic Pricing and Tiered Options

Simply tacking on a flat profit percentage to every single job is old-school thinking, and it leaves a lot of money on the table. A much smarter play is strategic pricing, where you adjust your margin based on the job's complexity, the client's needs, and what your local market will support.

One of the most effective ways to do this is by presenting "good, better, best" options. This simple move completely reframes the conversation. You're no longer just a price—you're a solutions provider.

Think about it from the homeowner's perspective:

- Good (Standard Efficiency): A solid, budget-friendly 14 SEER AC unit. This gets the job done and solves their immediate problem.

- Better (High Efficiency): A 16 SEER unit with a two-stage compressor. You can position this as the "best value" option, highlighting the long-term energy savings.

- Best (Premium System): The top-of-the-line 18+ SEER variable-speed system, complete with a smart thermostat. This is the ultimate comfort and efficiency package for the discerning customer.

When you offer choices, you empower the customer. You’d be surprised how often they choose a higher-margin option than the basic one you might have quoted otherwise. This approach positions you as a trusted advisor, not just an installer, and helps you maximize profit without getting dragged into a price war. It's all about demonstrating value, not just spitting out a number.

Avoiding Common Estimating Mistakes

Even seasoned pros can make a costly slip-up on an HVAC estimate. The real difference is that the best in the business learn from those mistakes and build systems to make sure they don't happen again. Think of this as your field guide to the most common—and expensive—blunders that can silently drain your profits.

These aren't just hypotheticals; they're the kind of real-world scenarios that play out on job sites every single day. The good news? Each one has a clear, practical fix you can put in place right away to protect your bottom line.

Underestimating Labor on Complex Jobs

It's one thing to budget a standard block of time for a simple unit swap-out. It's a completely different story when you're wrestling with a cramped attic, navigating an old home with crumbling plaster walls, or figuring out a tricky retrofit. That standard time goes right out the window, and failing to account for site complexity is one of the fastest ways to lose money.

A classic example I see all the time is forgetting the hours it takes just to protect the client's home. You have to lay down drop cloths, put on booties, and carefully maneuver heavy equipment through a fully furnished house. That time isn't "billable" in the customer's eyes, but it's a very real labor cost for your business.

Pro Tip: During your site visit, snap photos of all the access points and potential obstacles. I recommend adding a "Complexity Factor" line item to your estimate sheet. You can then assign it a percentage—like adding 15% to your labor hours for a nasty crawlspace—to formalize the adjustment.

Relying on Outdated Material Prices

The cost of copper, steel, and refrigerant can swing wildly in just a few weeks. If your price book hasn't been updated in six months, your entire estimate is built on a foundation of bad data. A job that looked perfectly profitable on paper can easily become a break-even project—or worse—by the time you actually order the parts.

Imagine bidding a big commercial job based on last quarter's coil prices. A sudden spike in copper costs you an extra $2,000 on materials, completely wiping out your profit margin before your team even sets foot on the property. This is where dedicated software that visualizes and manages these fluctuating costs becomes invaluable.

Forgetting the "Soft Costs" and Incidentals

The big-ticket items—the furnace, the AC unit, the thermostat—are hard to miss. But the small "soft costs" are the real profit killers that add up fast and slip through the cracks on busy days.

Your estimating process absolutely needs a checklist that forces you to account for these easily forgotten items. Things like:

- Permit Fees: These can vary dramatically from one town to the next and become a nasty surprise if they aren't in the quote.

- Subcontractor Costs: Will you need an electrician to run a new circuit? Or a specialist for asbestos abatement?

- Equipment Rentals: A crane for a rooftop unit or a specialized lift can cost hundreds, sometimes thousands, of dollars a day.

- Disposal Fees: Hauling away and properly disposing of old equipment and materials isn't free.

Forgetting a single crane rental can turn a profitable job into a major loss. By creating—and actually using—a pre-estimate checklist, you build a safety net that catches these costs before they ever hit your bank account.

Common Questions About HVAC Estimating

Even with a rock-solid process, you're going to run into questions when building an HVAC estimate. Getting the answers right is what separates the seasoned pros from the rest. Let's tackle some of the most common ones I hear.

What Is the Best Software for HVAC Estimating?

There’s no magic bullet here. The "best" software is the one that actually fits how your company operates day-to-day.

A smaller residential shop, for example, will probably get the most bang for its buck with an all-in-one field service management platform. These tools roll estimating, scheduling, invoicing, and customer history into one neat package. But if you're a larger commercial contractor bidding on complex, multi-phase projects, you'll likely need specialized software designed for heavy-duty mechanical takeoffs.

No matter what you choose, make sure it does these three things well:

- Lets you maintain an accurate, easily updated price book for parts and labor.

- Helps you generate professional, itemized proposals without a lot of hassle.

- Plays nicely with the scheduling and billing software you're already using.

How Do I Calculate My Overhead Markup?

Before you can even think about profit, you have to know what it costs to just keep the lights on. This is your overhead, and getting it right is non-negotiable.

Start by adding up every single indirect business cost for a full year. I'm talking about rent, truck insurance, marketing, office staff salaries—everything but the direct costs of a job. That final number is your total annual overhead.

Next, figure out how many billable hours your techs can realistically work in a year. Remember to account for drive time, training days, and other non-billable activities. Now, just divide your total annual overhead by your total annual billable hours. The result is your overhead cost per hour.

That hourly overhead figure has to be added to your burdened labor rate on every single job. That’s your breakeven point. Only after you’ve covered parts, labor, and this overhead can you start adding your actual profit margin.

How Can I Make My Estimates More Competitive?

The secret to being more competitive isn't always about being cheaper. It's about demonstrating more value. If you just slide a single number across the table, the customer has nothing to compare it to except a lower price from your competitor.

Change the game by presenting "good, better, best" options. Instead of one quote, offer a standard-efficiency unit, a high-efficiency model, and a premium variable-speed system. This immediately shifts the conversation from "How much?" to "Which of these is the right fit for my home?"

You should also make sure your proposal looks professional and clearly breaks down the costs. When a client sees exactly where their money is going, it builds a massive amount of trust. And don't forget to highlight your warranties, five-star reviews, and team certifications. Homeowners will gladly pay a little more for the peace of mind that comes with hiring a reputable company.

Should I Charge for Creating an HVAC Estimate?

This is a classic debate in the industry. For a simple, straightforward replacement quote that doesn't take much time, most contractors chalk it up to the cost of doing business and don't charge a fee.

But the moment a job gets complex, the rules change. If you're doing extensive diagnostic work, a manual heat load calculation for new construction, or designing a complicated system from scratch, you absolutely should charge a diagnostic or design fee. Your time and expertise are valuable.

The key is transparency. Tell the customer about the fee upfront. A great way to handle this is to offer to apply the fee as a credit toward the final project cost if they hire you. It shows good faith and gives them a real incentive to choose you for the job.

Streamline your entire estimating process with TackonFSM. From building accurate quotes with a pre-loaded pricebook to dispatching techs and getting paid faster, our all-in-one platform gives you the tools to protect your margins and grow your business. Discover how TackonFSM can transform your operations today.